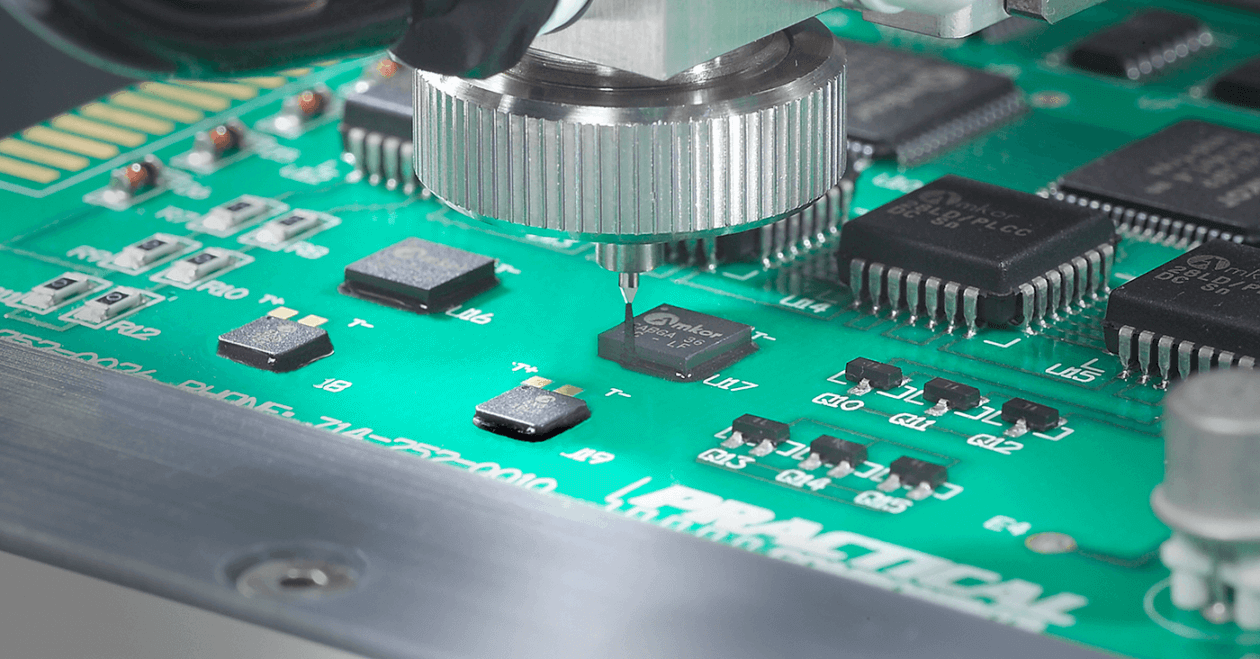

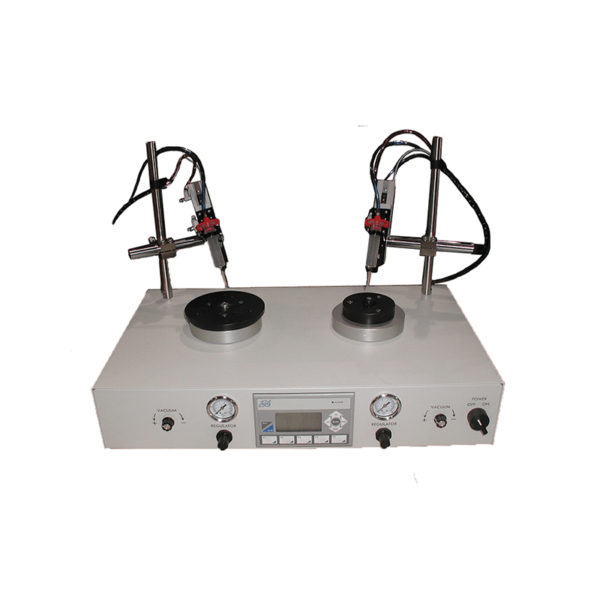

Dispensing can extend across numerous industries and applications that require dosing in an accurate and controlled manner. PVA’s award winning valves and pumps are available to dispense a broad spectrum of chemistries to meet the requirements of your most demanding applications.

White Papers

View allProducts

View all

Aluminum Jackets

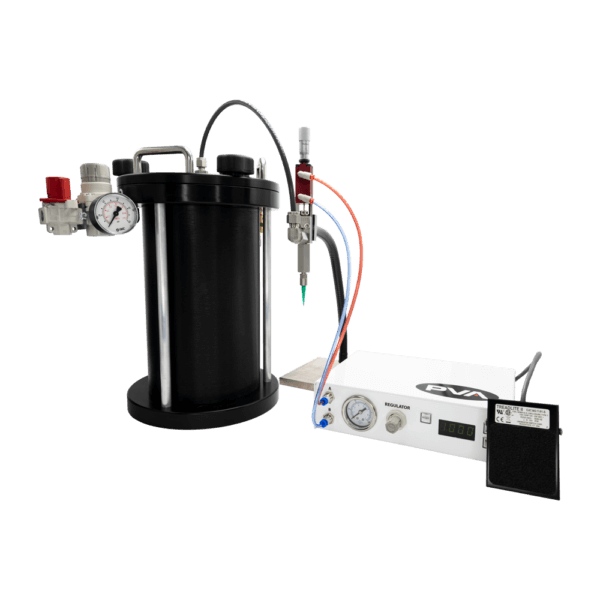

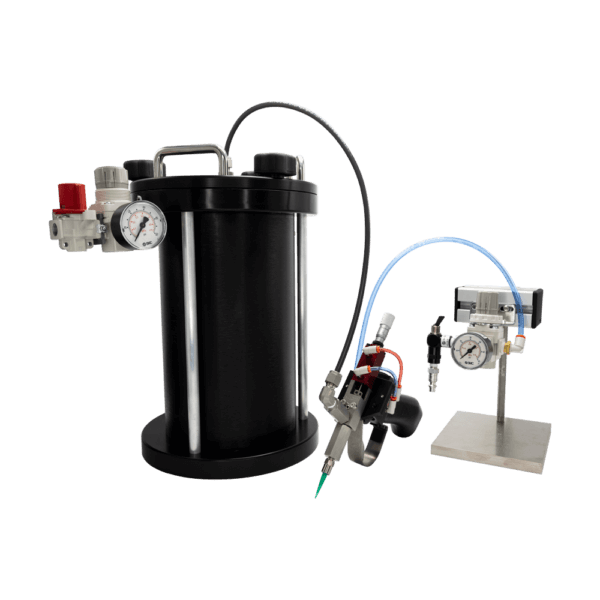

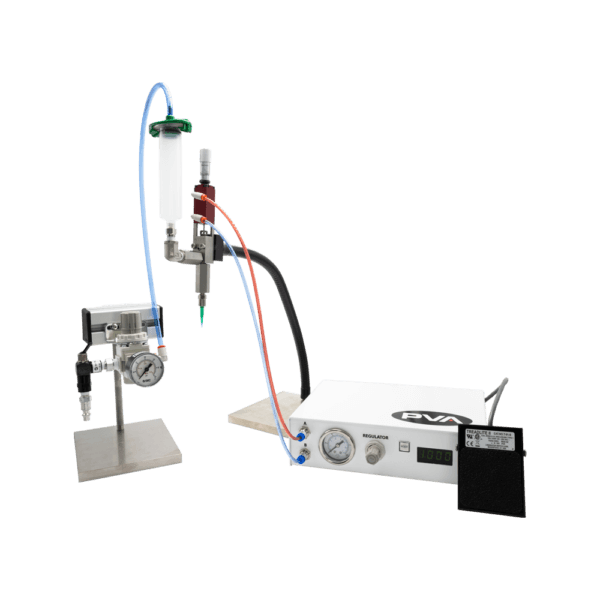

BP50

CA300

CA300-2LT-1-S

CA300-5LT-1-S

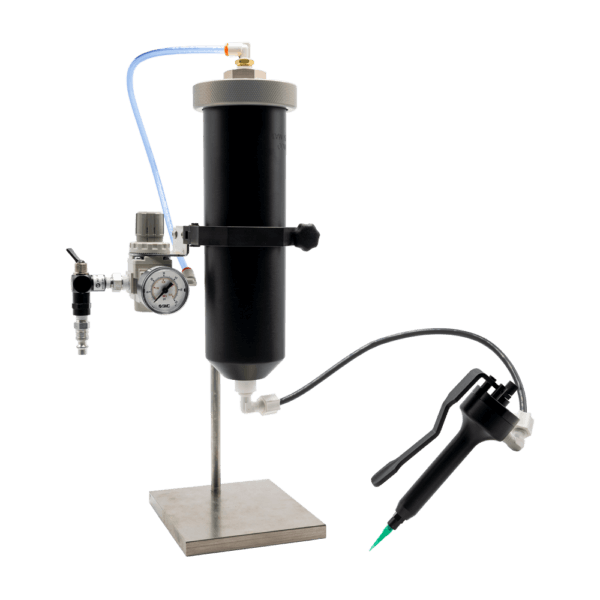

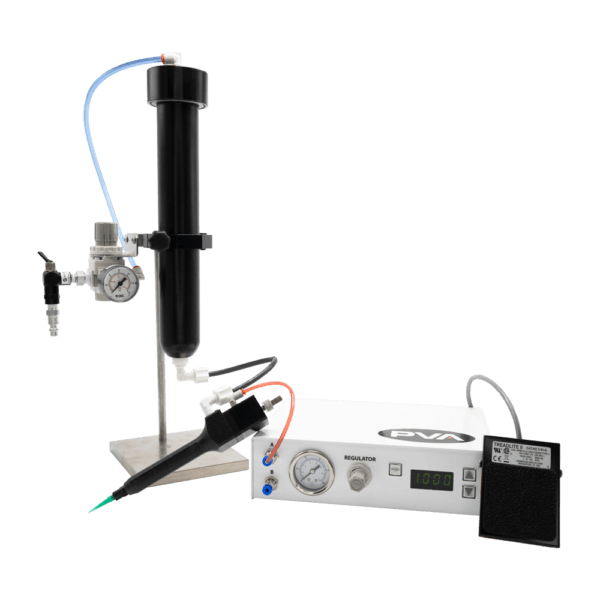

CA300-SYR-1-S

CAM200

CAM200-120-1

CAM200-200-1

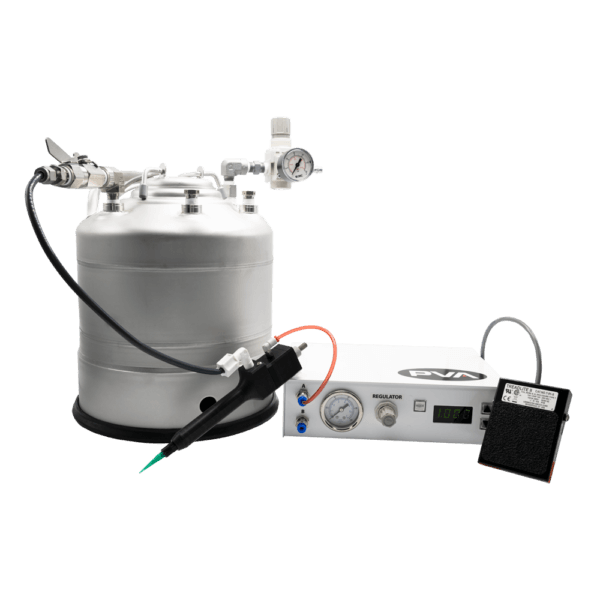

CAM200-2G-1

CAM200-2LT-1

CAM200-2LT-2

CAM200-5LT-1

CAM300

CAM300-120-1

CAM300-2G-1

CAM300-2LT-1

CAM300-5LT-1

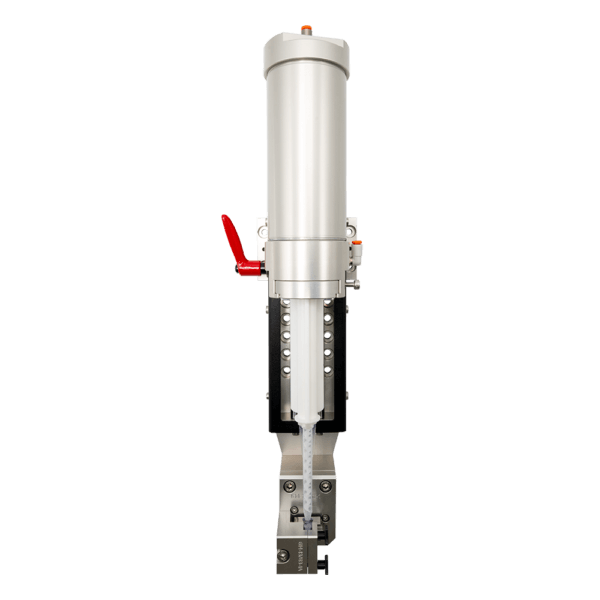

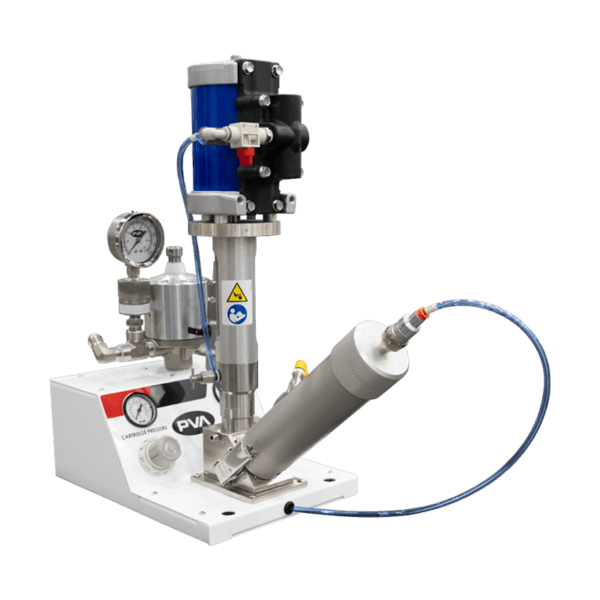

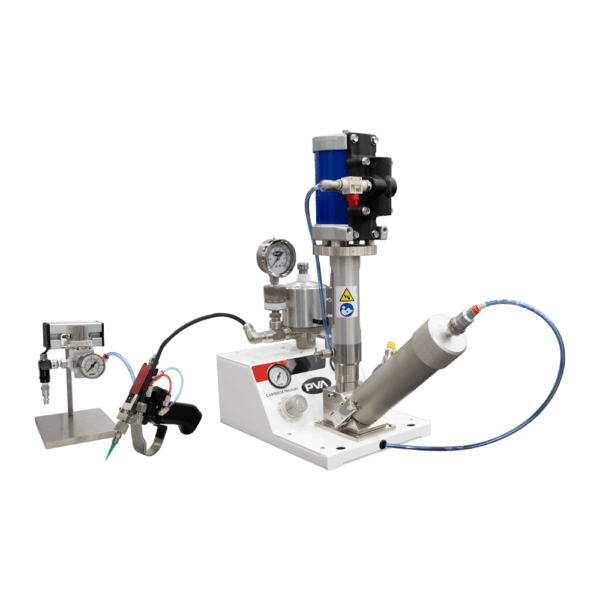

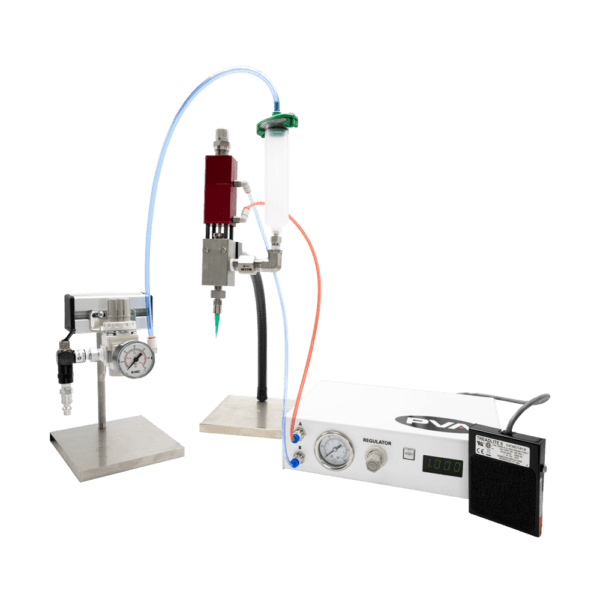

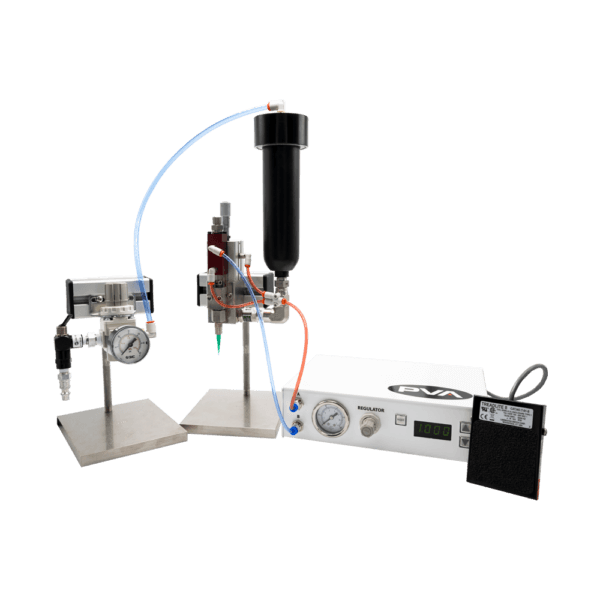

Cartridge Pump

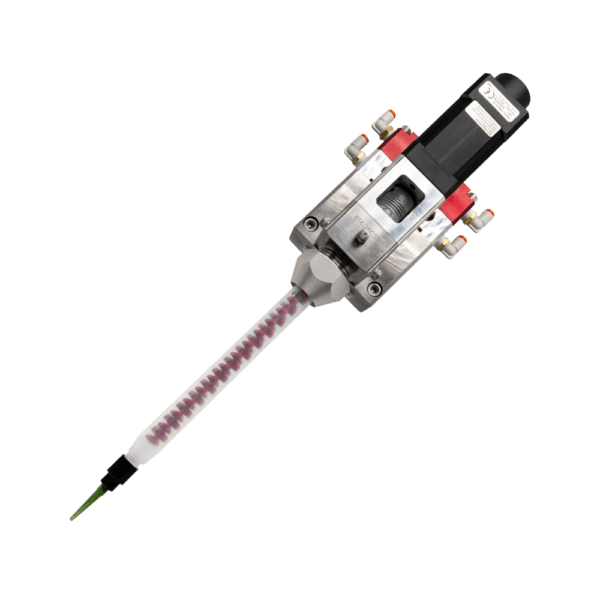

DX150 Series

FC100 Series

FC100-2G-H

FC100-2LT-1-H

FC100-2LT-1-S

FC100-300ML-1-H

FC100-300ML-H

FC100-5GPP-H

FC100-5LT-1-H

FC100-SYR-1-S

FC300 Series

G-Series Dispense Needles

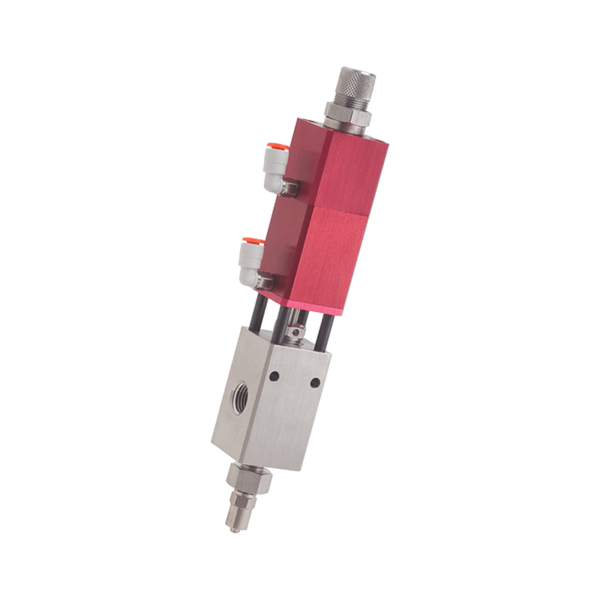

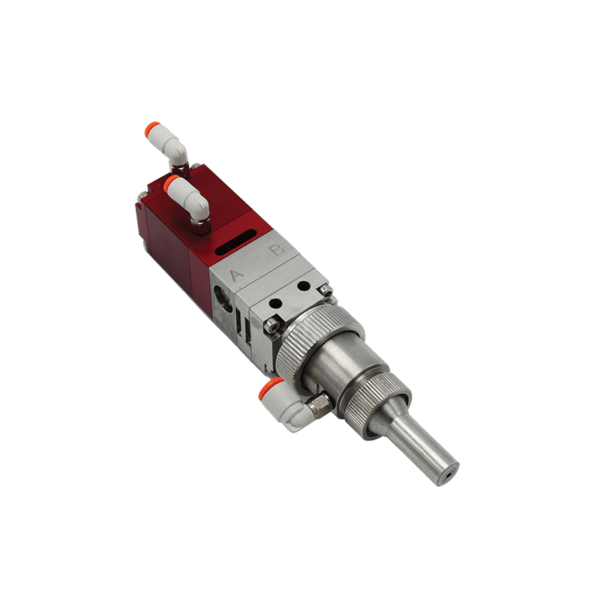

JDX

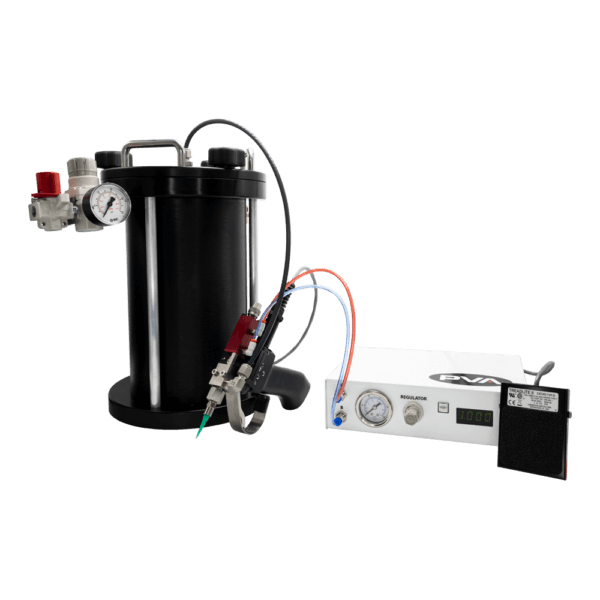

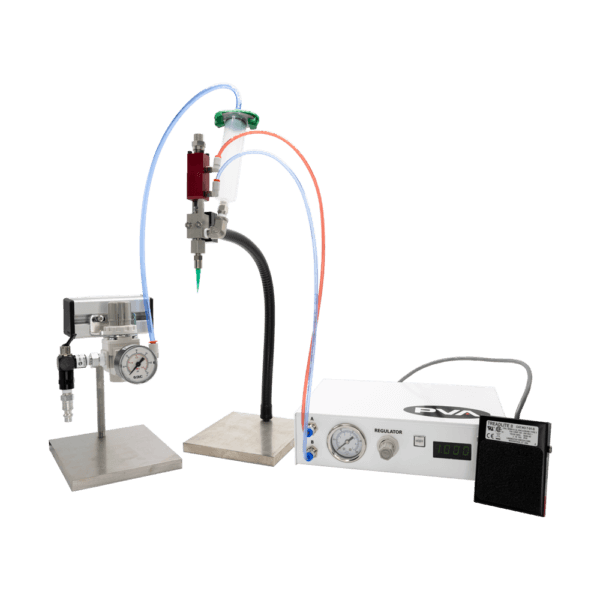

MCCS-SYS-12

MCCS-SYS-14

MCCS-SYS-5

Micro Dispense Nozzles

MR1

MR2

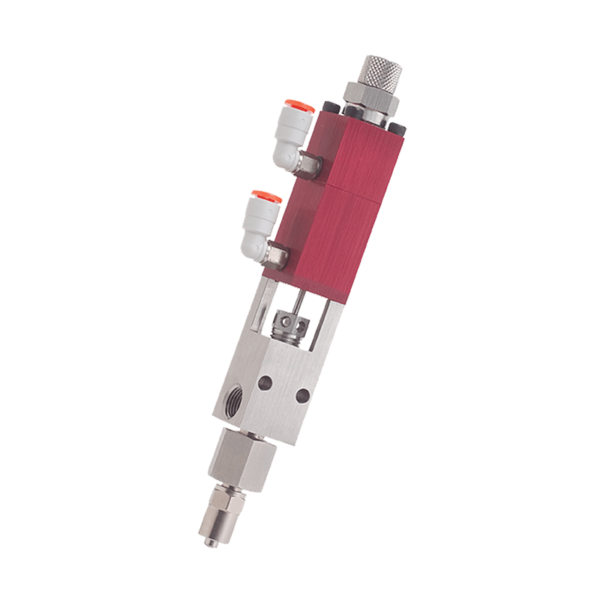

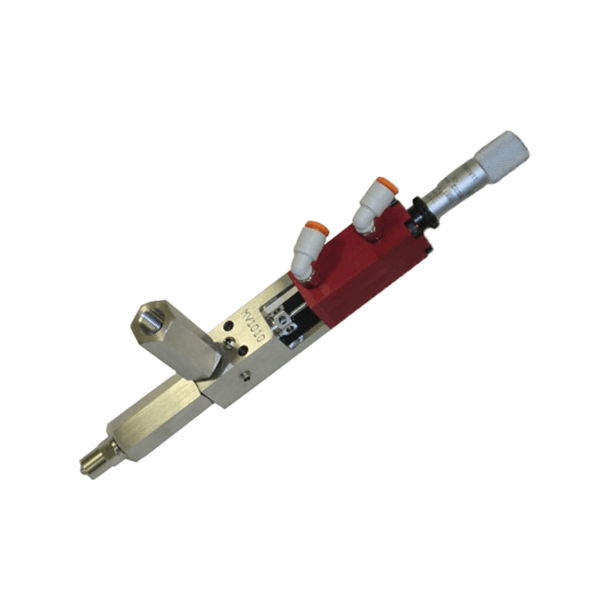

MV200

MV250

MV250-LL

MV250-LL-2LT-1-S

MV250-LL-2LT-H

MV250-LL-SYR-1-S

MV300

MV300-2G-1-S

MV300-SYR-1-S

MV500

MV500-060-1-S

MV600

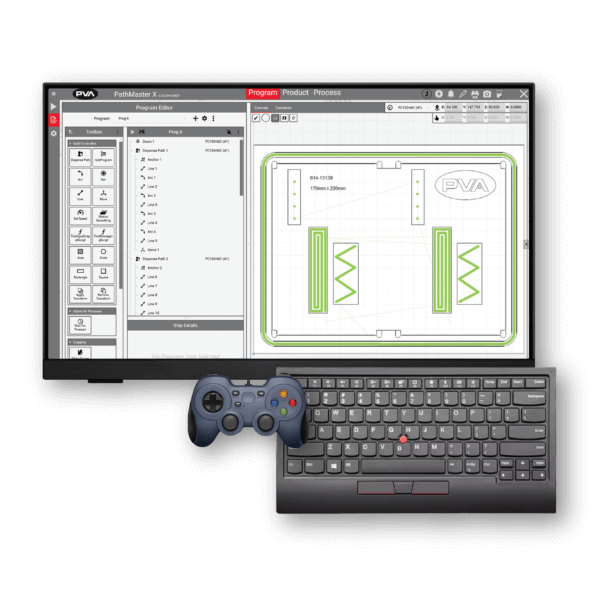

PathMaster X

PC100

PC150

PC200R-SS

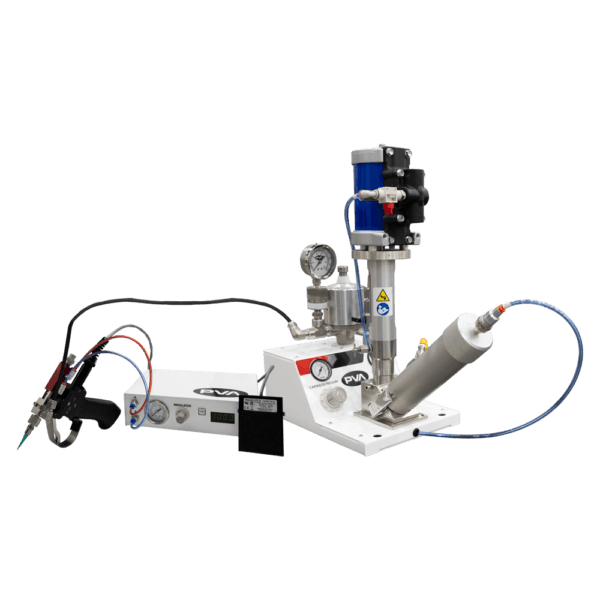

PCP

PCS150

PCTP

PDP

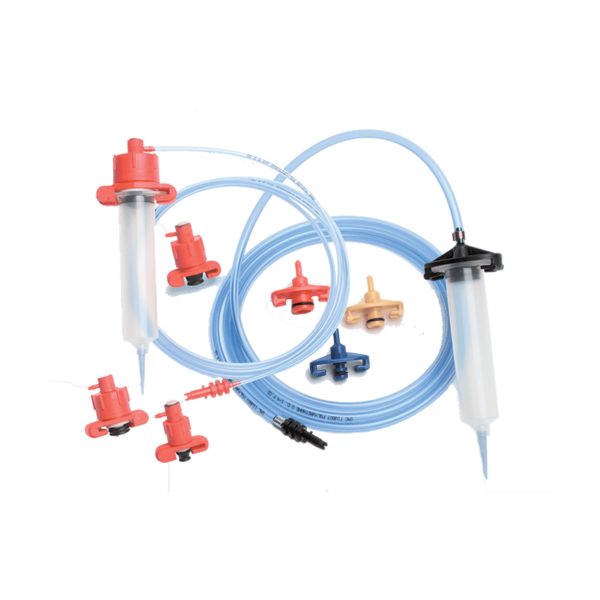

Precision Dispensing Tips Sample Kit

PVA 20/20

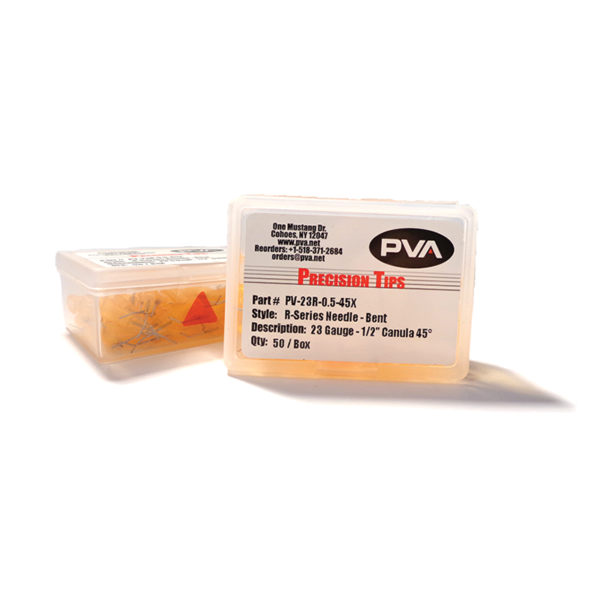

R-Series Dispense Needles

R-Series Dispense Needles – 45° Bend

R-Series Flexible Needles

R-Series Taper Tip Nozzle

RCC150

RD200

SB300 Series

SB400-C

SCTP

SGP

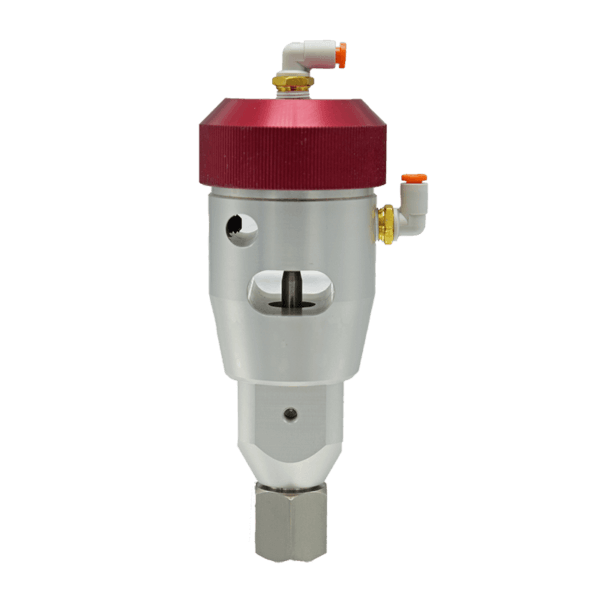

Smooth Flow Nozzles

SMR

SPP

ST100

ST100-S

SV200

SVC100

SVX

Syringe Air Adapters