Multi-Industry Expertise: PVA’s Array of Dispensing, Coating and Custom Automation

This article was originally featured in the August 2018 issue of U.S. Tech.

Originally a small business operated from the founder’s own home, Precision Valve & Automation (PVA) has grown into a global supplier. Throughout its rapid growth and success in a variety of industries, the company has never lost sight of its own small-town community.

Headquartered in Cohoes, New York, PVA is a supplier of conformal coating systems, advanced fluid dispensing solutions and precision valve technology. With regional sites throughout North America, Europe and Asia, the company has grown into a worldwide provider of fluid dispensing and spray systems for adhesives, sealants and coatings.

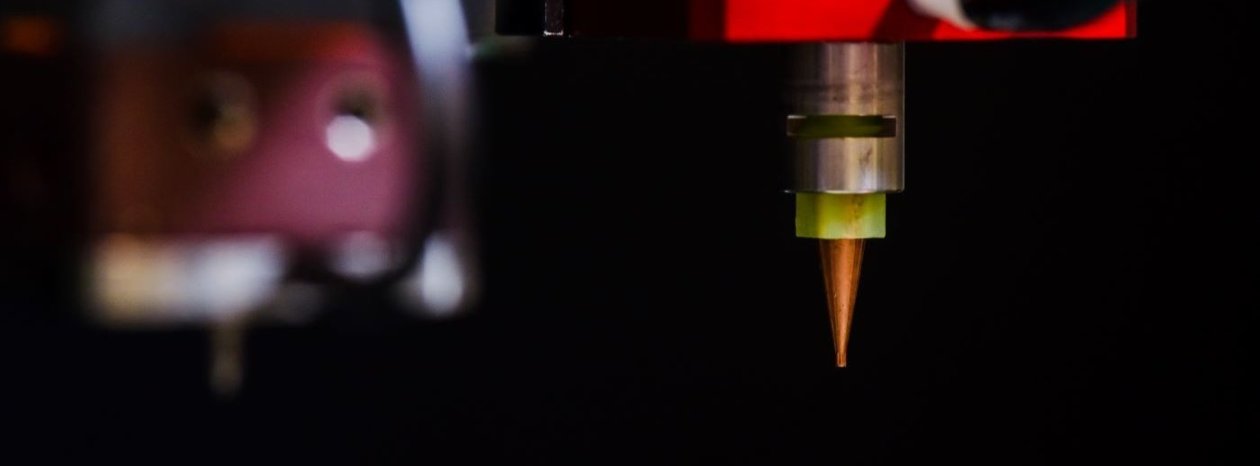

The company manufactures automated and manual dispensing equipment, spray coating equipment, pumps, and valves. Its selective conformal coating systems combine closed-loop process control, high levels of accuracy and repeatability for use in mid- to high-volume manufacturing environments.

Small-Town Roots

PVA was founded in 1992 by Anthony Hynes, president, when he began selling dispensing valves for automated and manual dispensing applications out of his home. Later that year, the company moved to Rensselaer Polytechnic Institute’s incubator center, where it began to build x/y/z robots to automate its developing valve technology.

Later that year, the company sold its first automated dispensing system. After that, PVA’s product line grew rapidly to include technology for accurately applying conformal coating materials. In 1994, the company debuted a selective conformal coating system that would later become the PVA2000, which improved on existing x/y/z plotting systems. This was due to a closed-loop servo-controlled process that proved both accurate and rugged.

That same year, Invotronics in Canada became PVA’s first selective coating system customer. Local, national and industry accolades followed as the company’s reputation grew, becoming a serious contender in the fluid dispensing market.

Many manufacturers rely on PVA’s conformal coating systems, fluid dispensers and custom automation products. The company offers customer-driven solutions for a variety of industries.

“From benchtop equipment to inline conveyor systems, we evaluate each opportunity independently, and without limitation, to ensure our customers make the most reliable product possible,” says Frank Hart, PVA’s sales and marketing manager. “Throughout the changing global manufacturing landscape, we remain committed to providing customers with exceptional products and industry leading global support.”

The company’s customer-driven systems are used in a variety of industries. Its technology, knowledge and flexibility allow the company to develop customized solutions that best fit the users’ process requirements. All systems are backed by a 24-hour global service network, including quick-response, regionally trained technicians.

Many Industries Served

PVA provides equipment for a broad range of applications, including adhesives and sealants, automated dispensing, coating, curing, custom automation, manual dispensing, microdispensing, and SMT and semiconductor dispensing applications. For electronics, including smartphone manufacturing and LCDs, the company’s automated and manual solutions are designed to provide accurate, reliable dispensing of lubricants, solvents, sealants, adhesives, and pastes.

In the automotive industry, there are many dispensing applications, from selective spray coating to potting, gasketing and bead dispensing, as well as applying adhesives and lubricants. For medical device manufacturing, the company offers equipment for handheld prototyping applications up through largescale manufacturing. PVA systems are used for plastic, glass and metal bonding, lubrication, coating, as well as dispensing UV adhesives for bonding cannulae, catheters and other components.

The military and defense market is known for high-mix, low-volume applications and unconventional boards. In this market, PVA’s machine flexibility and patented four-axis option has made the systems valuable. PVA’s systems are used in numerous renewable energy applications to ensure reliable products in the solar assembly process, including solder paste dispensing, edge and frame sealing, junction box potting and attachment, thinfilm backside coating, and electrical connection sealant and grease.

Combining flexible custom solutions with diverse applications expertise allows the company to meet a variety of needs in general packaging as well. PVA is an excellent equipment source for dispensing hot melt adhesives, doming materials, sealants, epoxies, and spray coat finishes for packaging.

The company offers selective conformal coating systems, automated dispensing, meter mix dispensing equipment, SMT adhesives, valves, coating inspection, inline curing ovens, optical bonding, board handling, valve controllers, manual dispensing and coating systems, material delivery tanks and pumps, coating and dispensing options, dispensing consumables, programming software, and fume extraction and filtration.

Community Involvement

“From modest beginnings in Upstate New York, to 105,000 ft2 (9,755m2) facility in Cohoes, and sites around the world, PVA has a long history of providing innovation and expertise in dispensing, coating and custom automation,” says Hart.

PVA has stayed true to its small-town roots, earning it a reputation as a community leader. Through its Fast Break Fund, the company contributes money and resources to developing educational programs that provide children with opportunities to succeed academically and athletically. The program provides sports summer camp scholarships to children from families with low incomes and sport clinics to children with developmental disabilities.

PVA strives to provide the technological innovation its customers need, while giving the care and concern that its community deserves.