PVA Featured in Medical Design Briefs

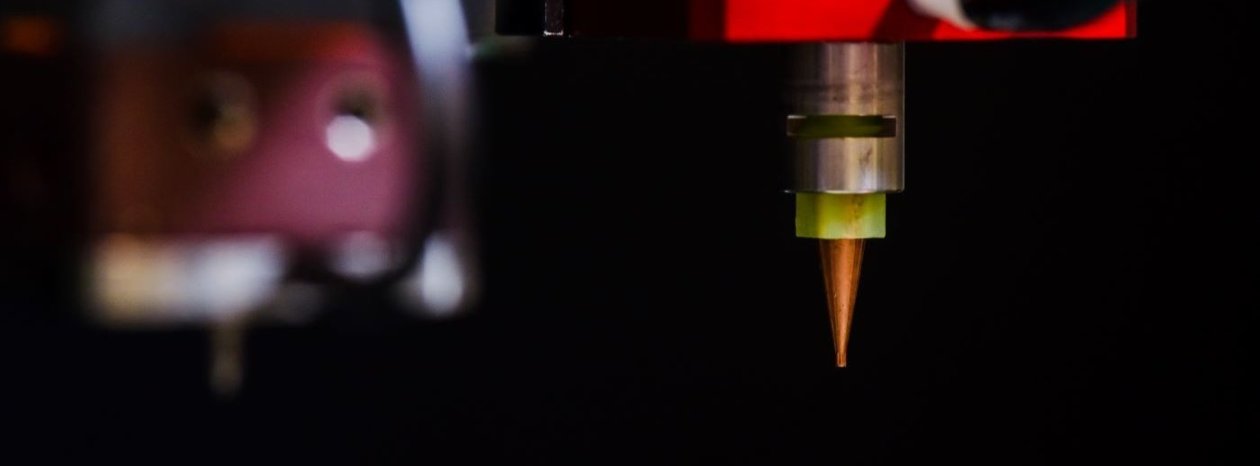

A revolution is upon us. Dispense pump technology innovation is quickly bringing improved accuracy, capability, and versatility to medical device manufacturers. This revolution not only opens the doors to creating production processes that were once unimaginable, but also increases the scope of chemistries that manufacturers can consider for these applications. The end result? Greater flexibility in achieving accurate results for small deposits of fluid with the option to choose rapid curing adhesives that reduce work in progress while improving bond strength.

Manufacturers worldwide are relying on their suppliers to use this updated technology and implement new processes. They are quickly turning in their syringes and the variability present in time and pressure dispensing processes for more accurate alternatives. This is particularly relevant in applications requiring smaller dose volumes. Simple time and pressure dispensing systems typically carry a 5–10 percent variation in volumetric accuracy. As manufacturing demands have required smaller deposits, that level of process variation is often unacceptable and physically unachievable in a manual process. Dispensing technology that can provide 1–2 percent shot-to-shot consistency is becoming the norm.