Using Liquid Thermal Interface Materials in Electronics Manufacturing

By Jon Urquhart, Global Applications Engineering Director, PVA

In the rapidly expanding world of electronics manufacturing, heat management has become a critical aspect of the design and assembly process. Whether designers are looking to get faster data rates from processor chips or create dense, high-power devices used in electric vehicle infrastructure, it has become more challenging than ever to effectively dissipate heat from the device. This is where thermal interface materials (TIMs) come into play.

While TIMs come in pad or liquid form, liquids are most commonly used and offer advantages over thermal pads, such as higher thermal conductivity, better conformability to irregular surfaces, reduced thermal resistance, and flexibility in the manufacturing process. Thermal pads are typically made of materials such as silicone or foam with conductive particles and provided pre-cut to size. In these days where design and manufacturing flexibility are key, dispensing liquid TIM offers a much more favorable process.

There are several types of liquid TIMs available, including thermal grease, gap filler, and thermal gel. Thermal grease is a silicone or metal-based paste that is dispensed onto to the component surface before a heat sink is mounted. Gap filler is made up of a two-component silicone formulation that provides adhesive properties between the two mating surfaces and not only thermal dissipation. The third type of TIM is thermal gel, which is a one-part silicone or urethane product with paste-like consistency that acts like a thermal pad but is in a dispensable liquid form.

The types of TIMs mentioned above are not all used in the same applications. Thermal grease is commonly used in applications where a higher thermal conductivity is required, such as high-power CPUs for data or graphics or in devices with very thin gaps between the device and heat sink. Gap filler is commonly used where the end product may see high vibration. The thermal gel is often used in devices where rework-ability may be needed, or the module needs to be easily disassembled in the future. Both gap filler and thermal gels are also used in applications where distance between the mating surfaces may be relatively large and not allow direct contact between the devices.

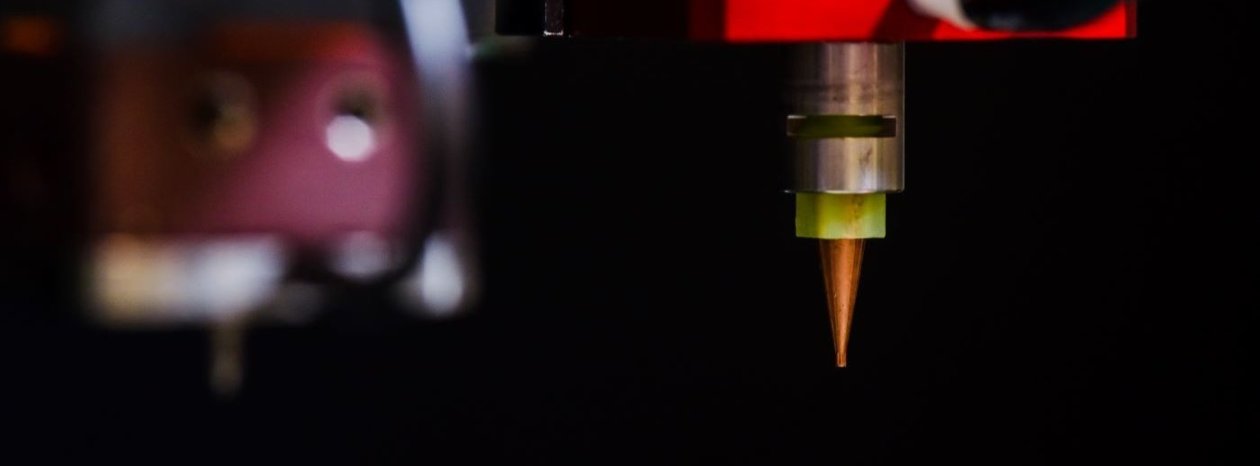

The application of thermal interface materials is no small feat and should be closely monitored. Most of these formulations include highly abrasive, conductive particles that can wreak havoc with traditional dispensing equipment, either by quickly wearing down components or packing into restricted spaces and rendering the system unusable. Dispensing TIM requires understanding of the liquid and a focus on fluid system design in order to maximize device life and maintain the integrity of the TIM during dispensing. Everything from pump design to fluid routing to materials used in the wetted components should be considered when designing a TIM dispensing system. Simple choices such as smooth flow fittings and eliminating sharp bends in the fluid path can help maintain fluid flow velocity and prevent separation and packing of fillers. Other considerations such as using abrasion resistant materials like carbide for valve sealing rods, or simple, low-cost seals that are easy to replace, can help prolong the time and cost of rebuilds.

Thermal interface materials play a critical role in the manufacture of electronic devices of all shapes and sizes. Dispensing of TIMs has become a standard process for many new devices and the diverse nature of this process is enabling manufacturing efficiencies for an evolving future.