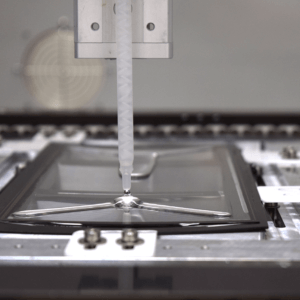

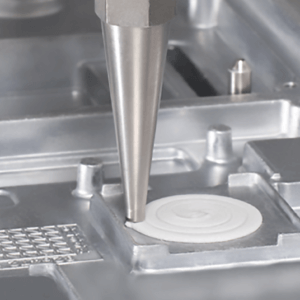

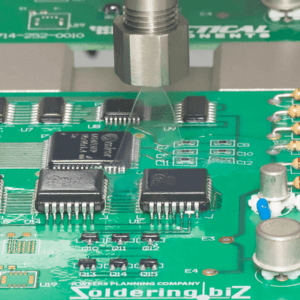

Conformal Coating

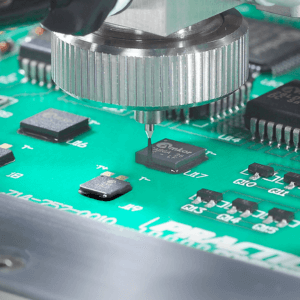

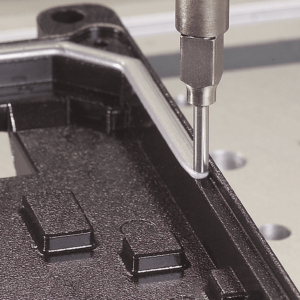

The application of a protective film or layer of liquid onto a PCB, either in selected areas or over the entire assembly. Conformal coatings are applied using an array of technologies such as atomized spray, airless film, needle dispense and jetting.