Curing Conformal Coatings: Pro Tip #18

PVA Pro Tip #18: Strategies for Optimal Cure in Solvent-Based Coatings

Navigating the Heat

Exposing a coated substrate to elevated temperatures can accelerate the cure schedule for heat cure and solvent-based conformal coatings. Developing an oven profile that matches your coating is essential to a successful process.

Solvent-based coatings require a moderate ramp to the desired cure temperature. Slowly introducing heat allows solvents to evaporate prior to solidifying the film. Introducing too much heat, too quickly, can cause the outer layer of the coating to cure and entrap solvent looking to evaporate. Bubbles in your coating, particularly adjacent to components, can be a telltale sign that you are introducing too much heat immediately after coating.

Coatings that are 100% solids and possess no solvent can be aggressively heated to reach optimal cure temperature quickly.

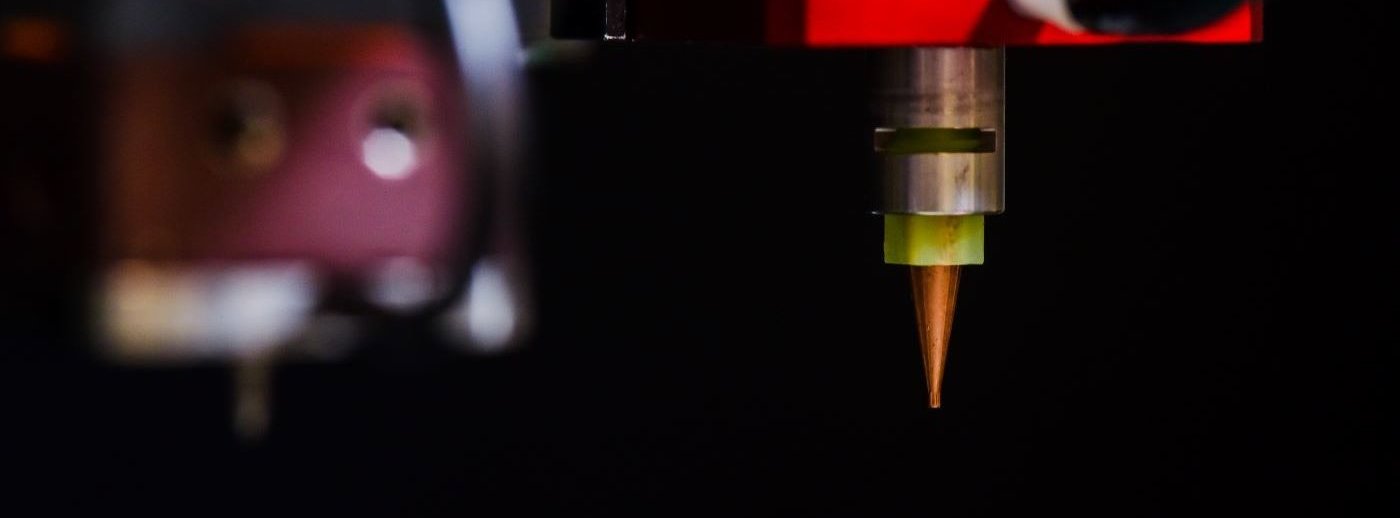

The DeltaTherm infrared oven precisely controls your heated curing profile. Infrared energy warms your substrate from the inside-out, thus avoiding premature skinning that traps bubbles under the coating surface. Multiple oven lengths are available to meet your throughput requirements.

For more information about our coating and curing solutions, contact PVA today and let us help make you a pro.