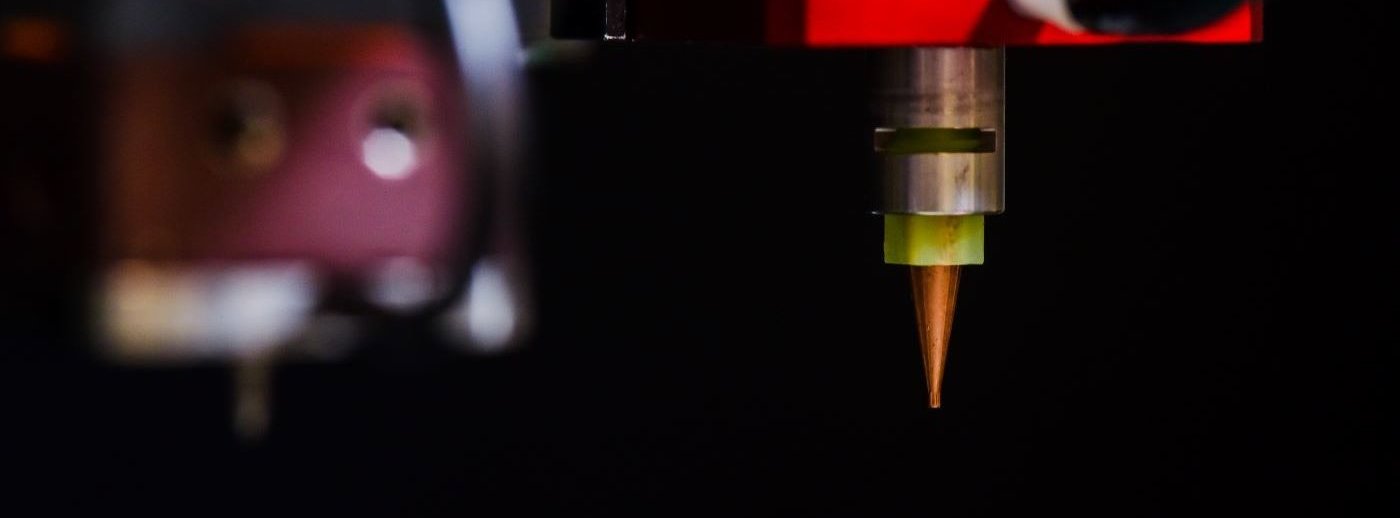

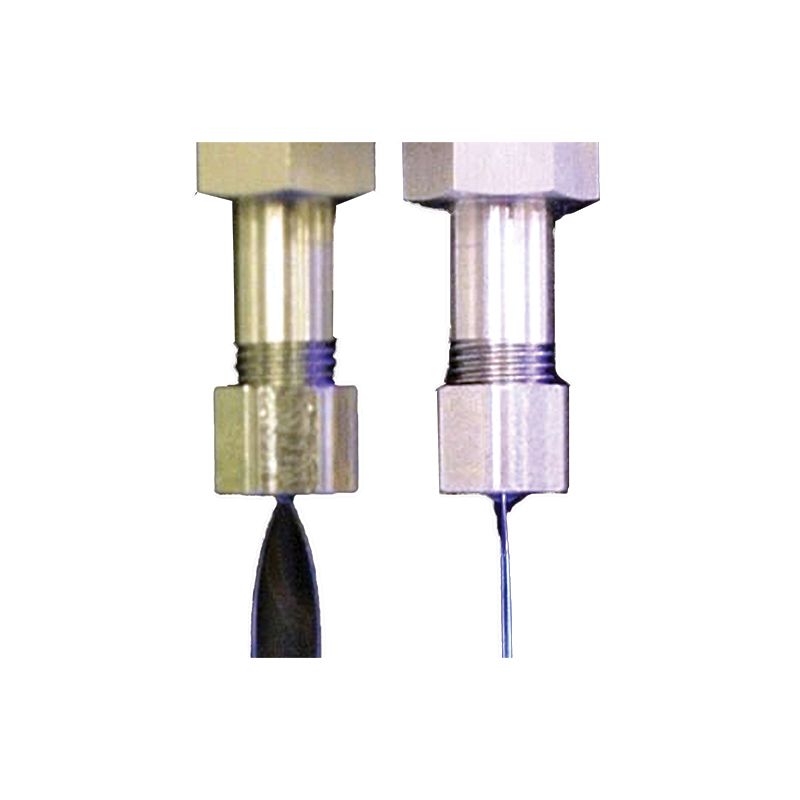

The application of a protective film or layer of liquid onto a PCB, either in selected areas or over the entire assembly. Conformal coatings are applied using an array of technologies such as atomized spray, airless film, needle dispense and jetting.

White Papers

View allProducts

View all

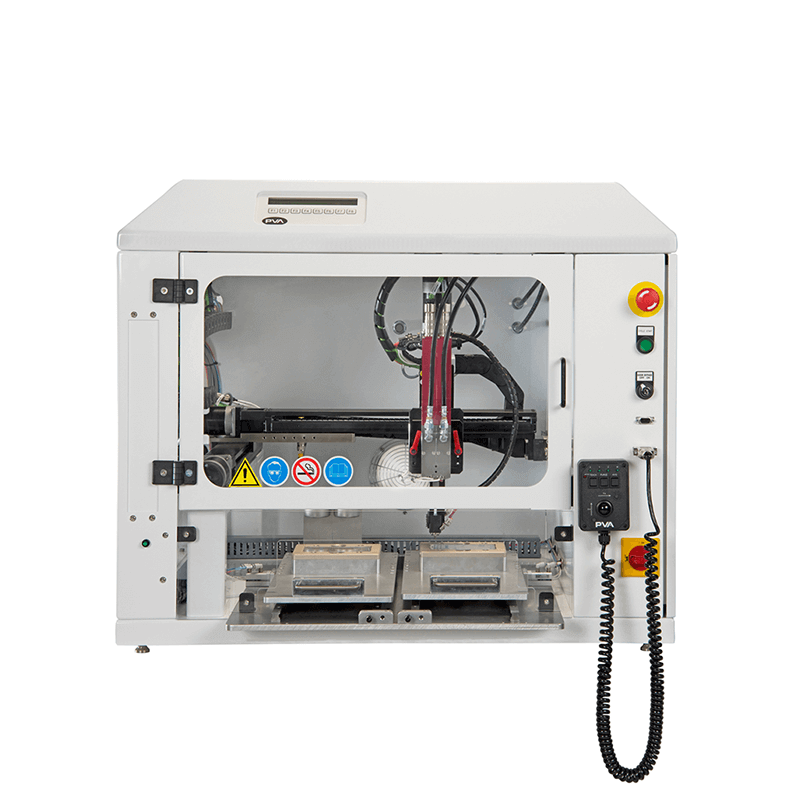

CAM200-2LT-1

CAM200-2LT-2

CAM300-120-1

CAM300-2G-1

CAM300-2LT-1

Continuous Film Calibration

Delta 6

Delta 8

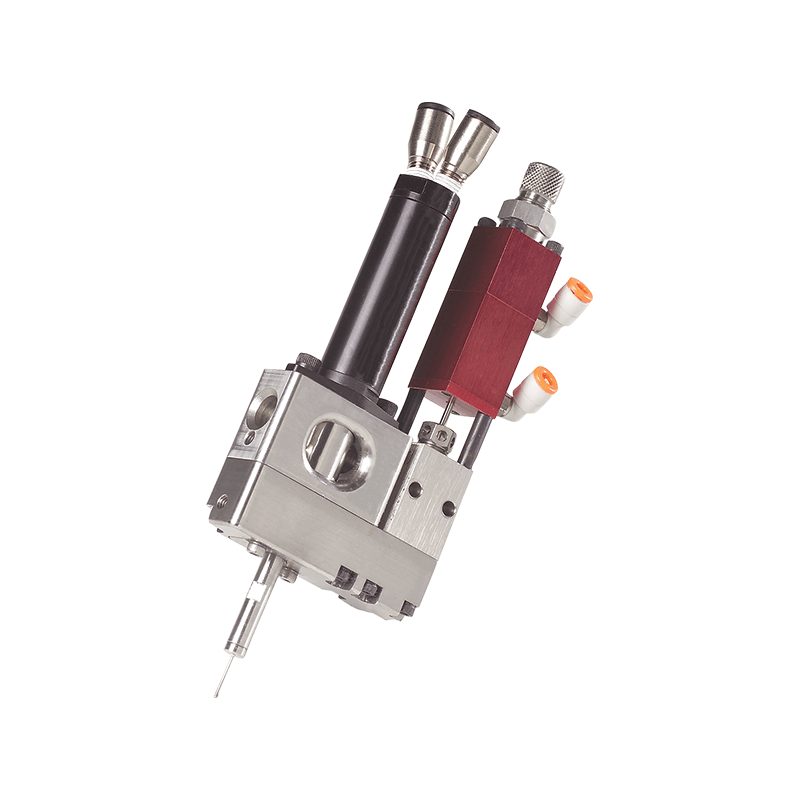

ES Ultra Fine

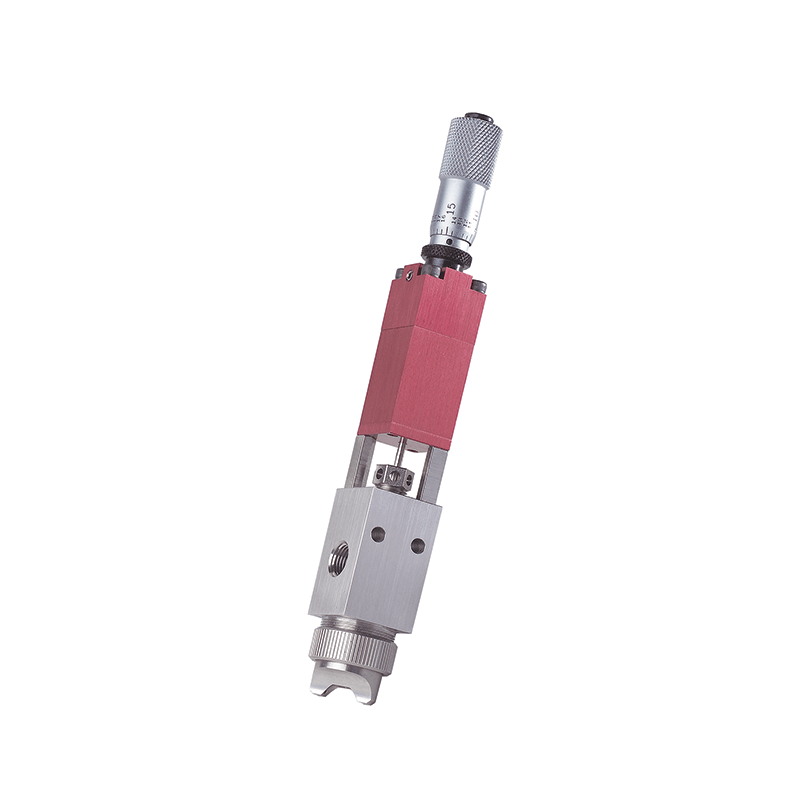

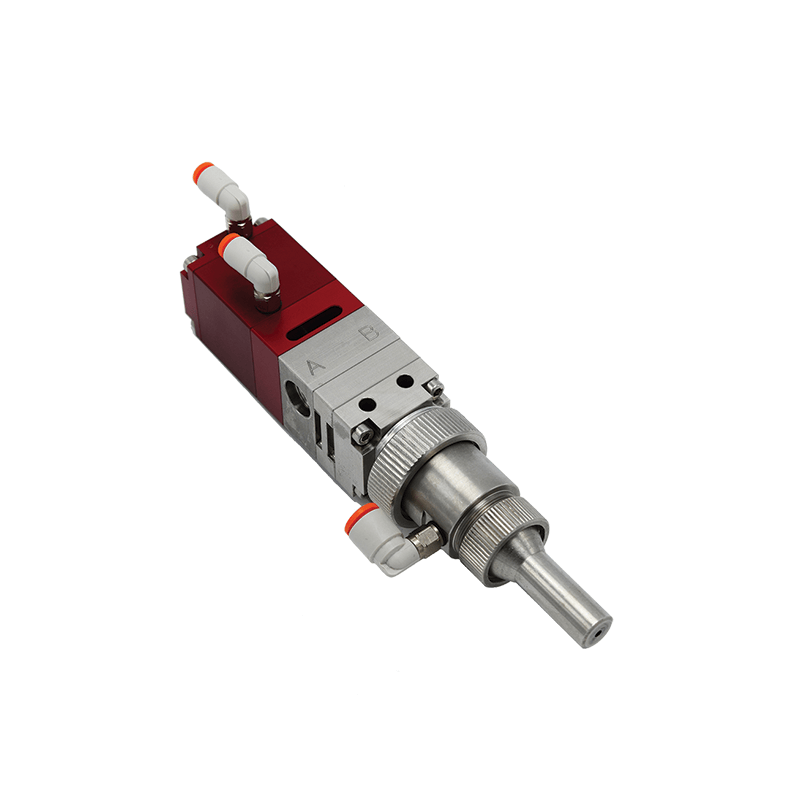

FC100-CF

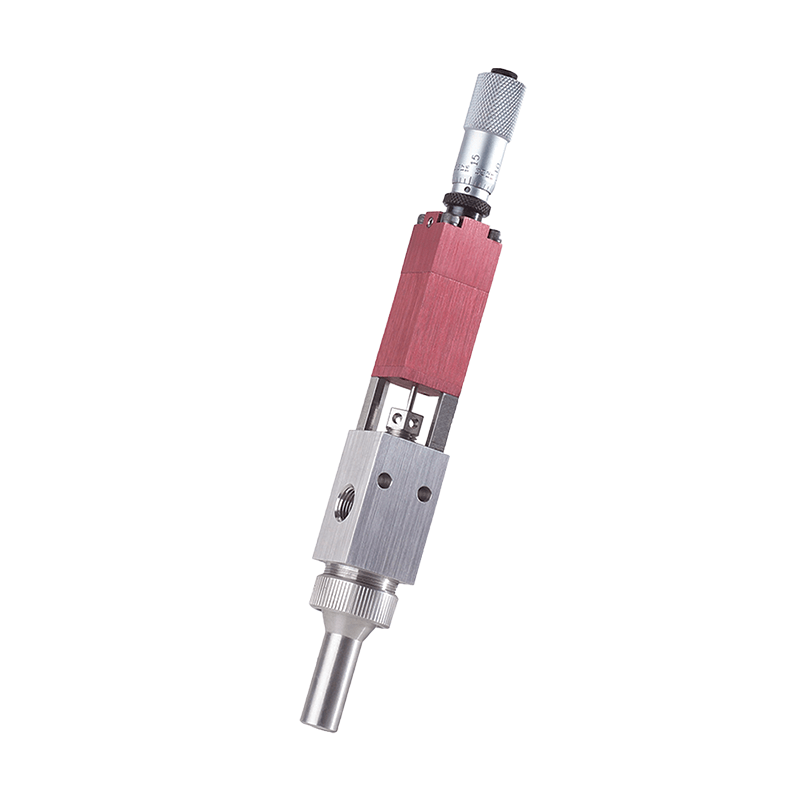

FCM100

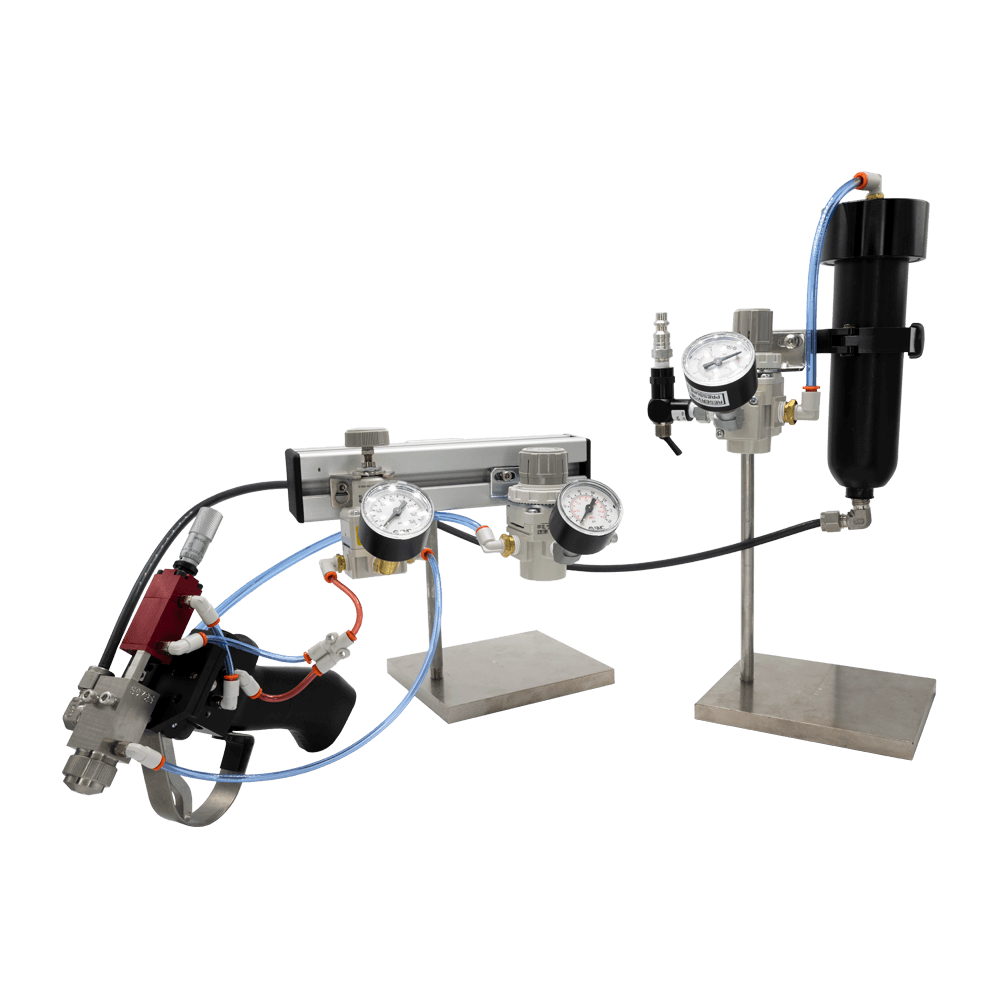

FCM200

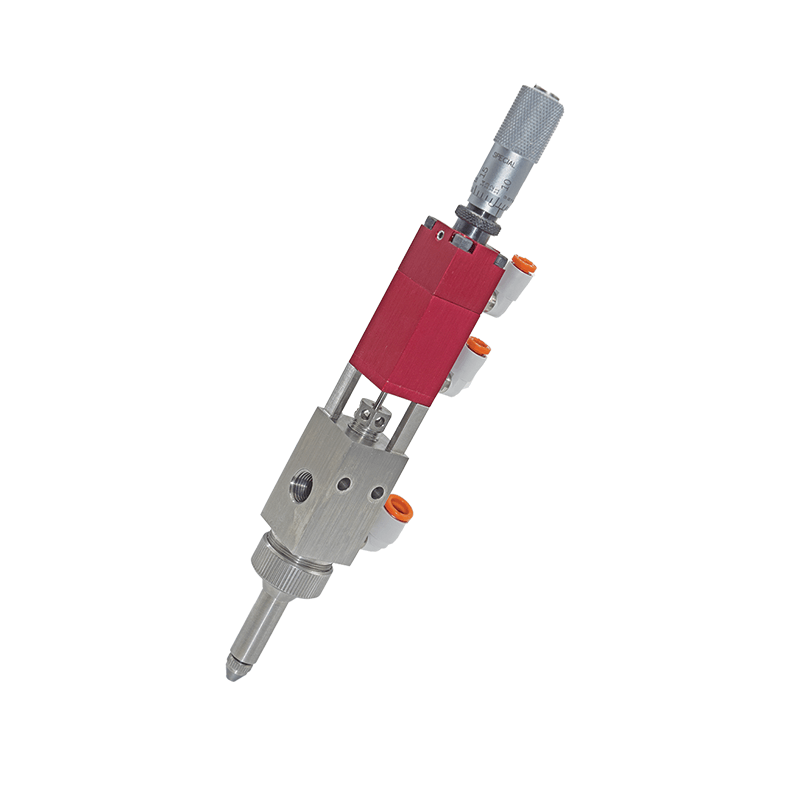

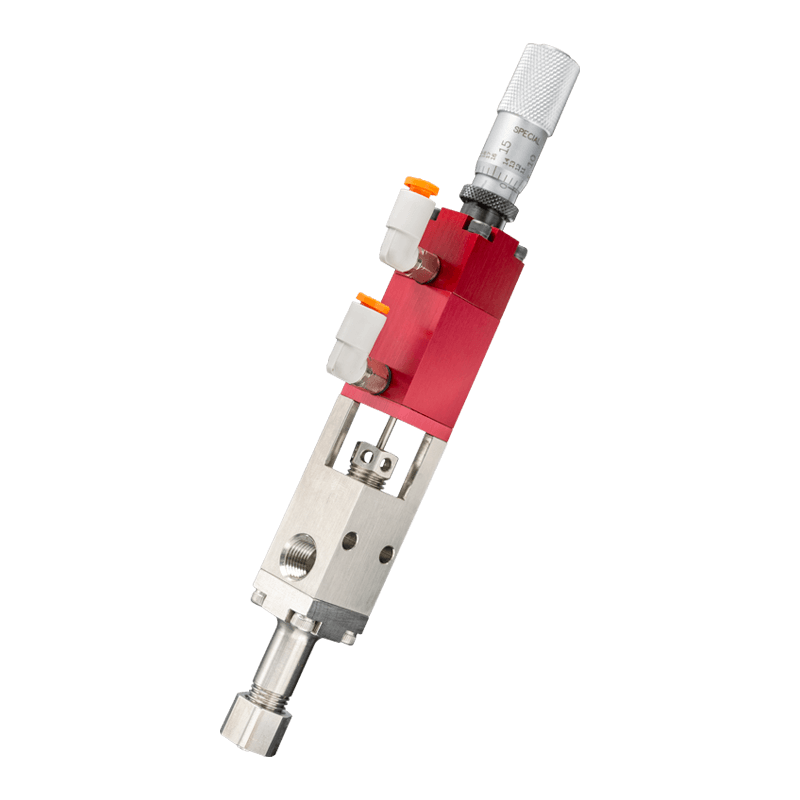

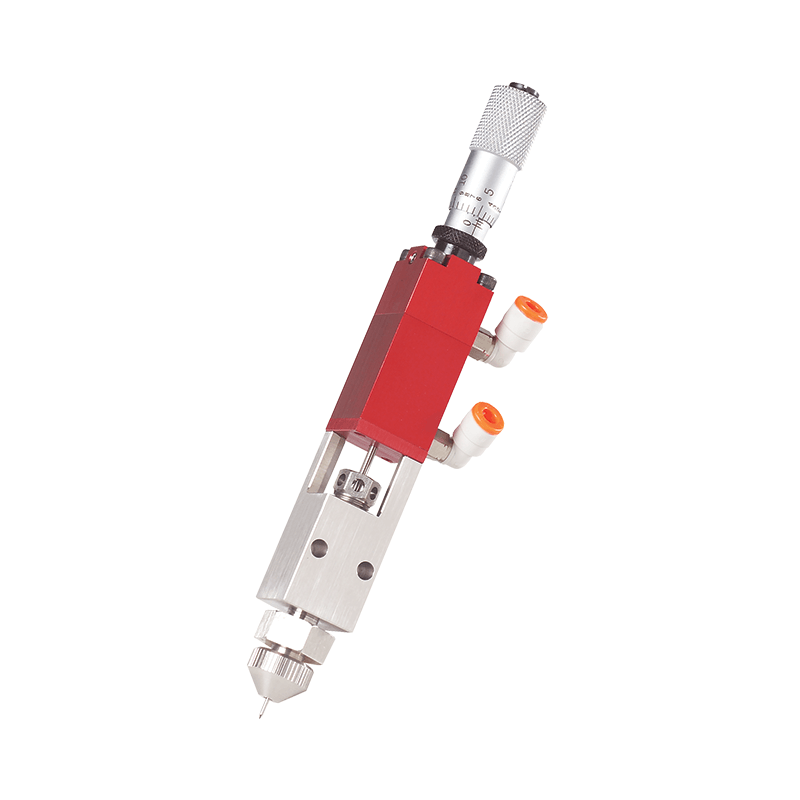

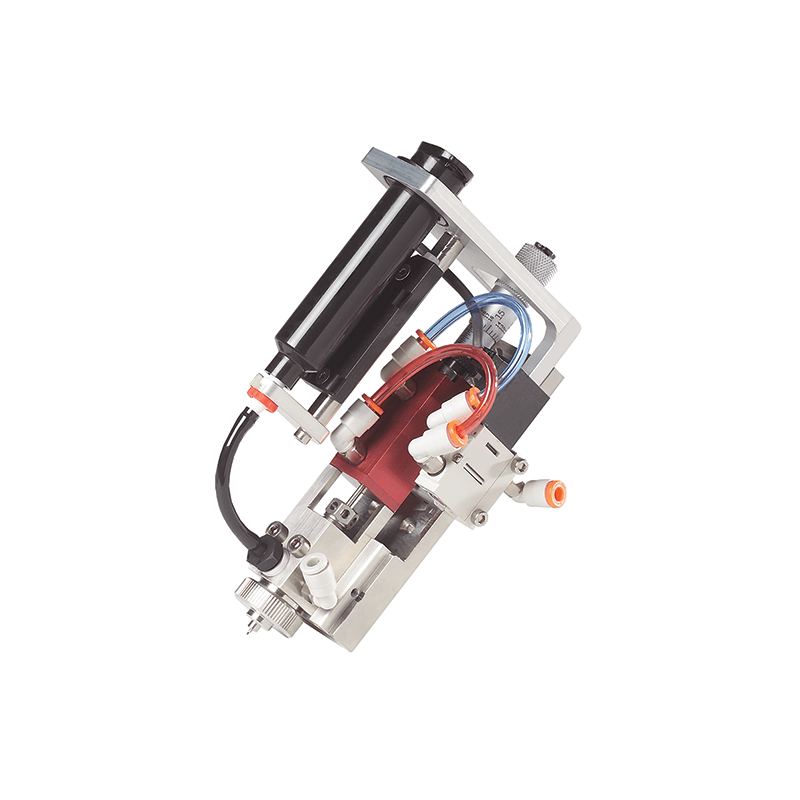

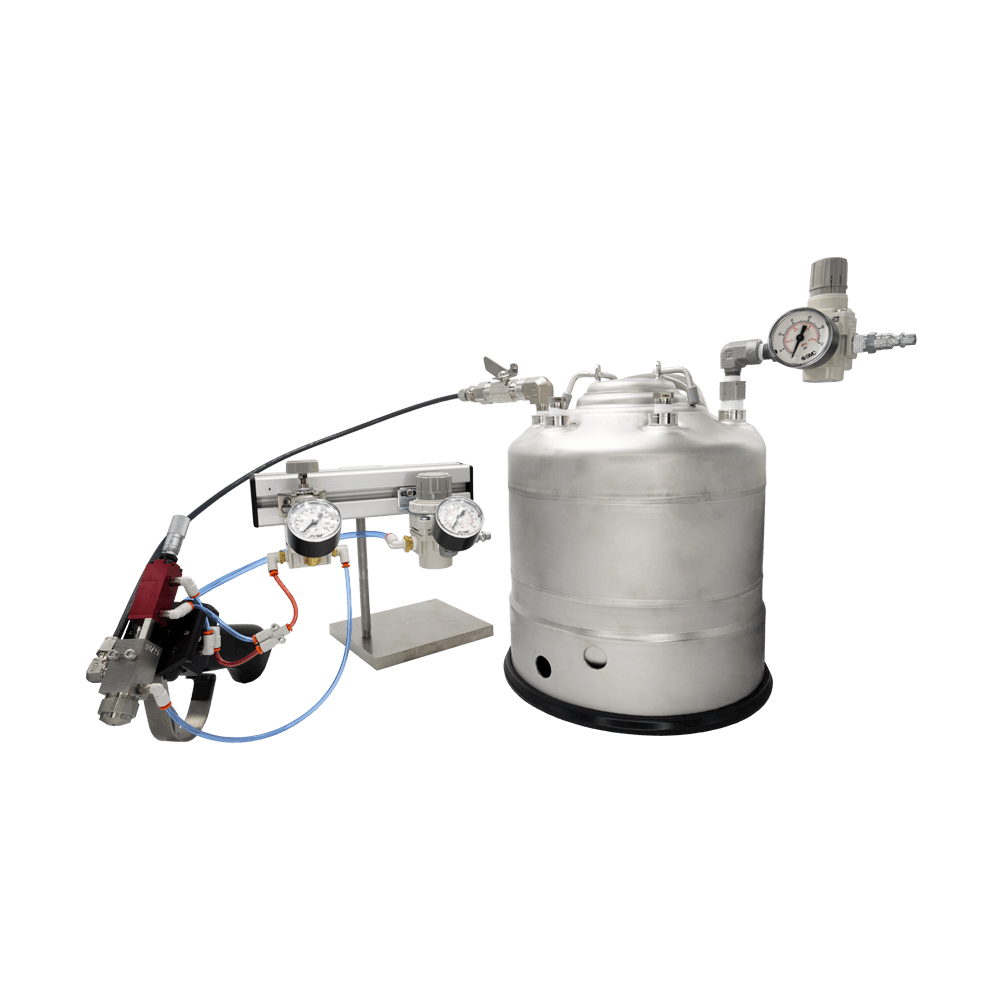

FCS300 Series

FCS300-ES Series

FCS300-R-060-H

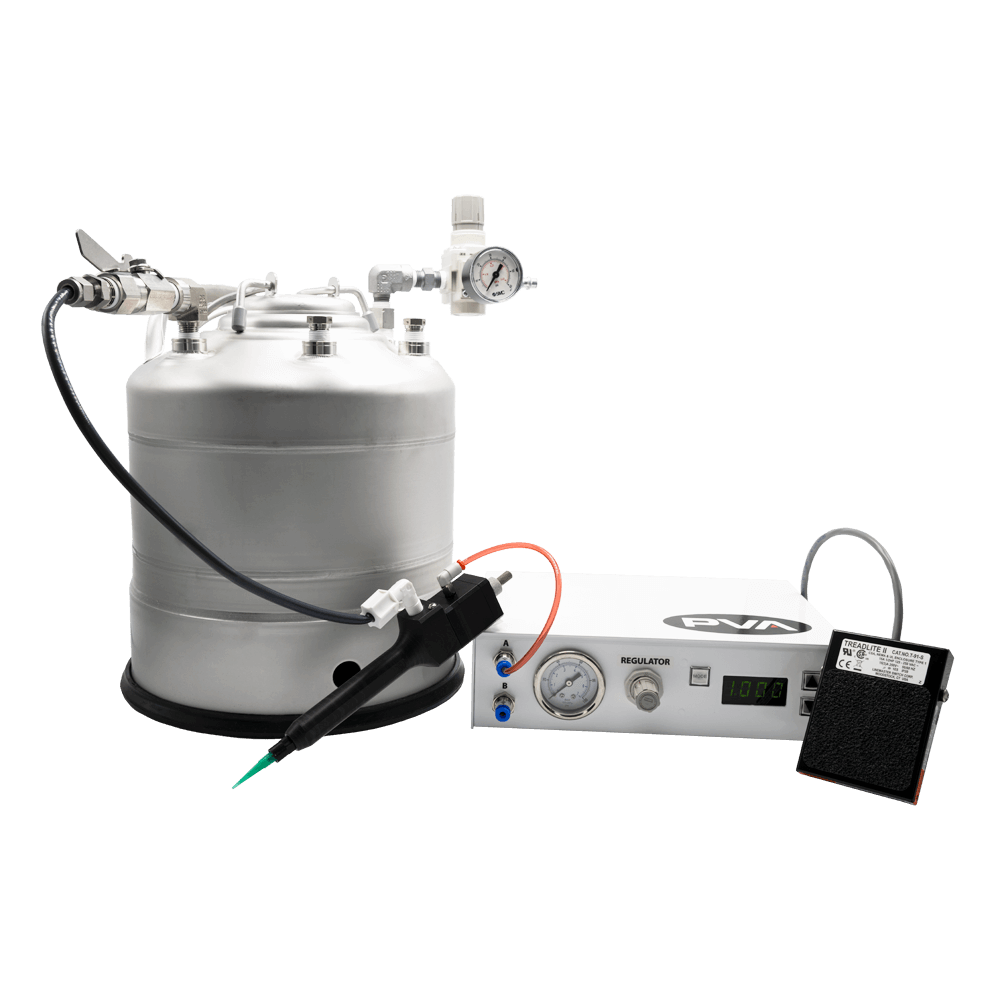

FCS300-R-2G-H

FCS300-R-2LT-1-S

FCS300-R-2LT-H

FCS300-R-5LT-H

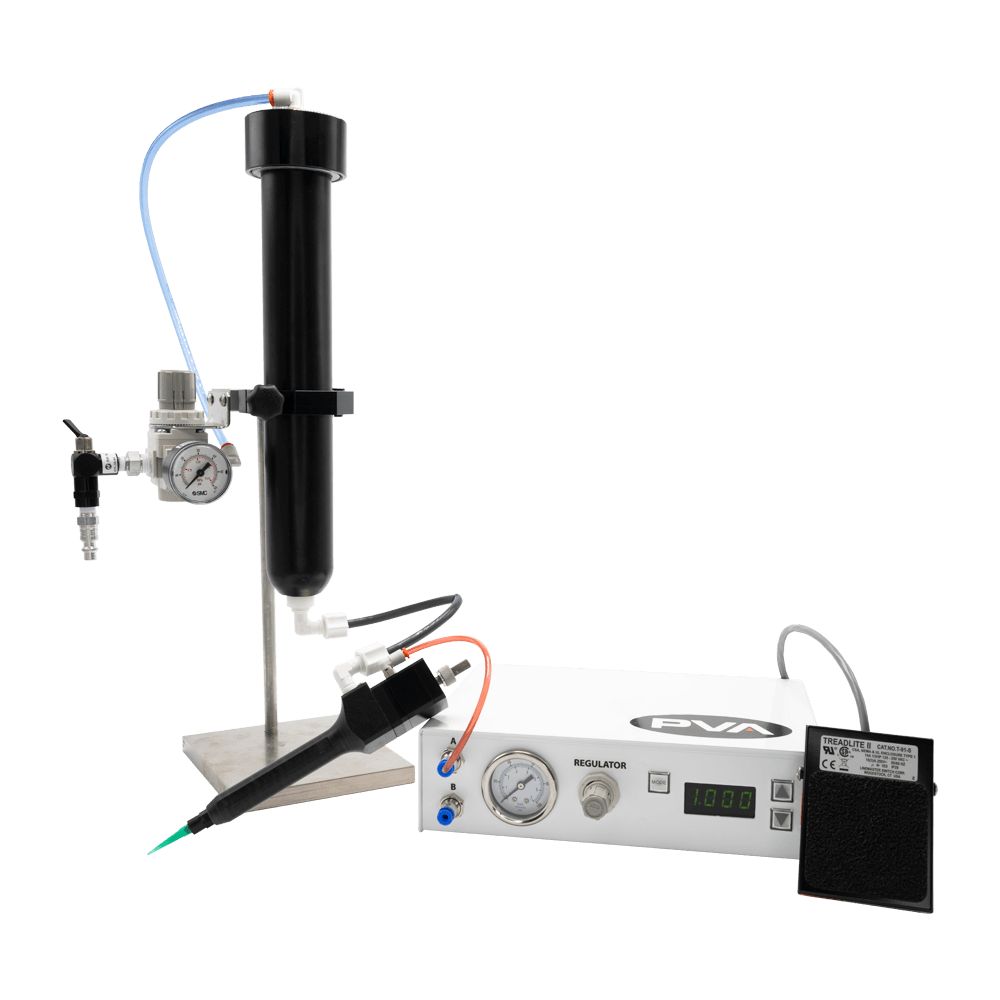

FCS300-R-SYR-1-S

FCS300-R-SYR-H

Flex Cell

JDX

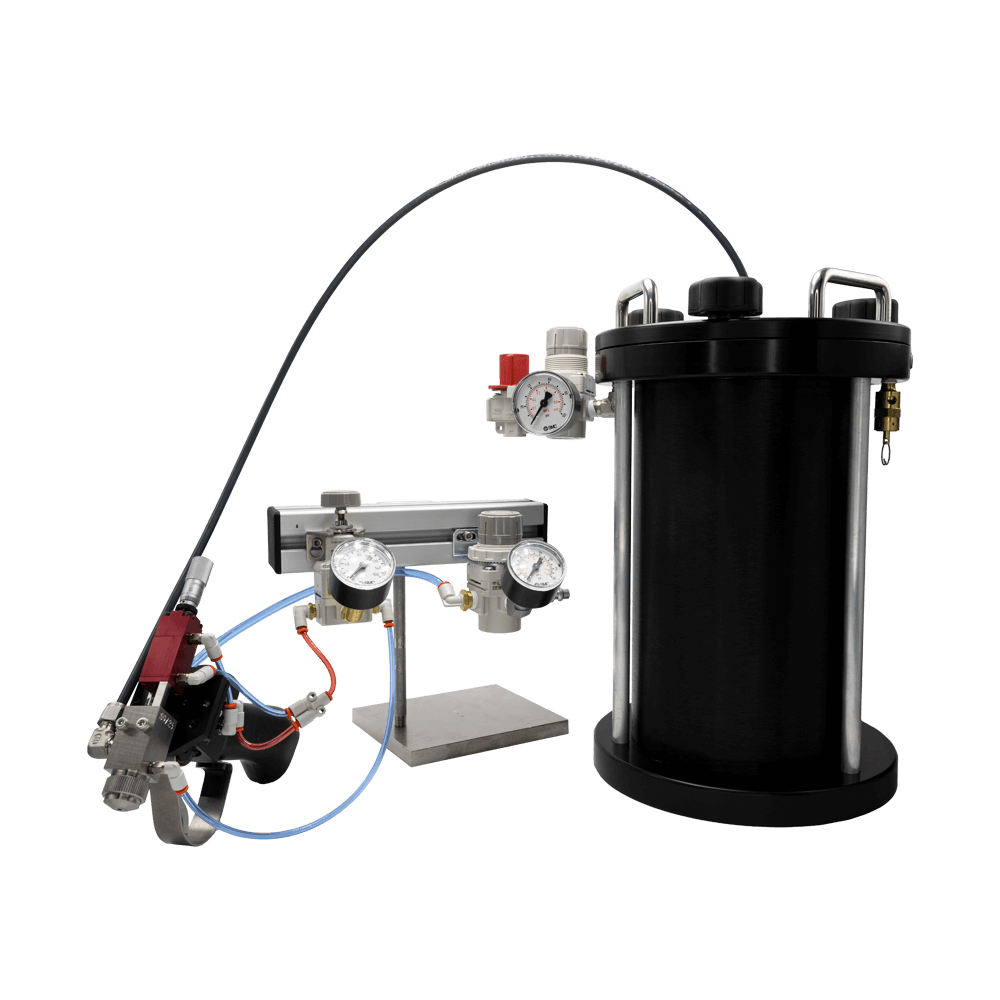

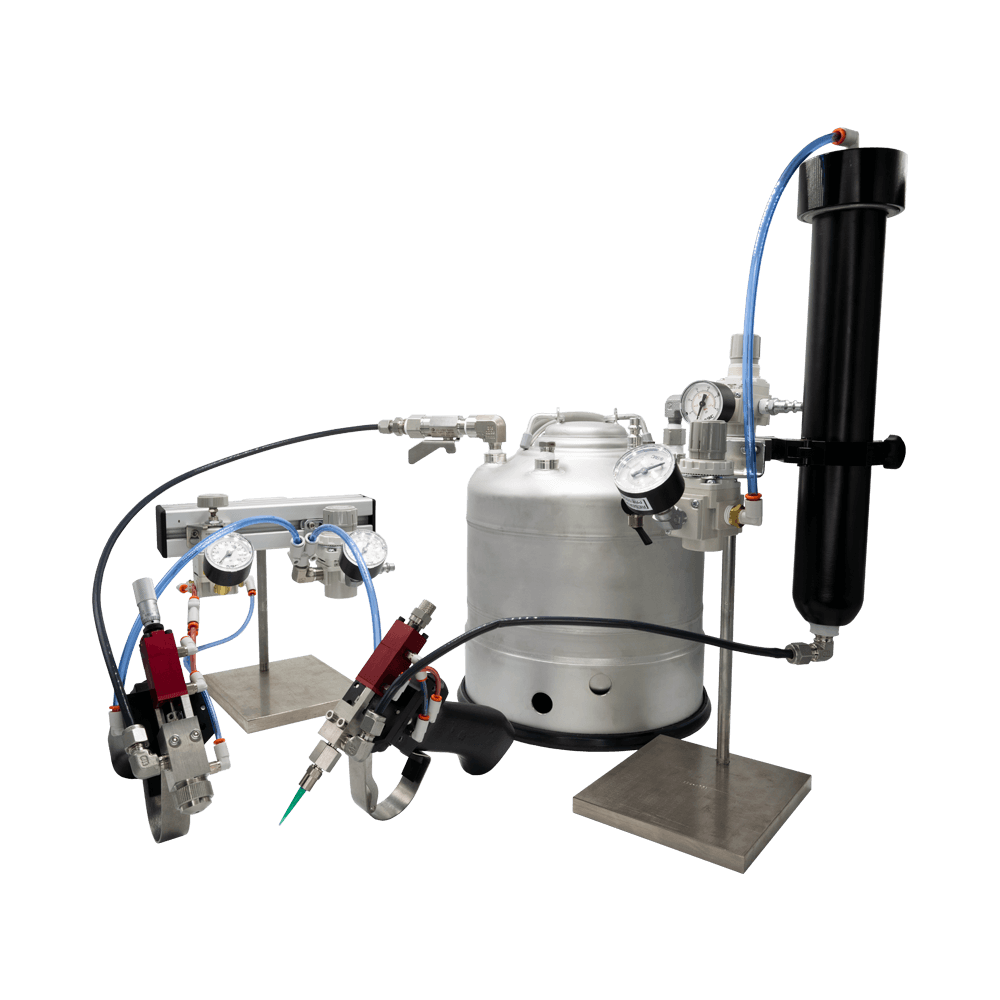

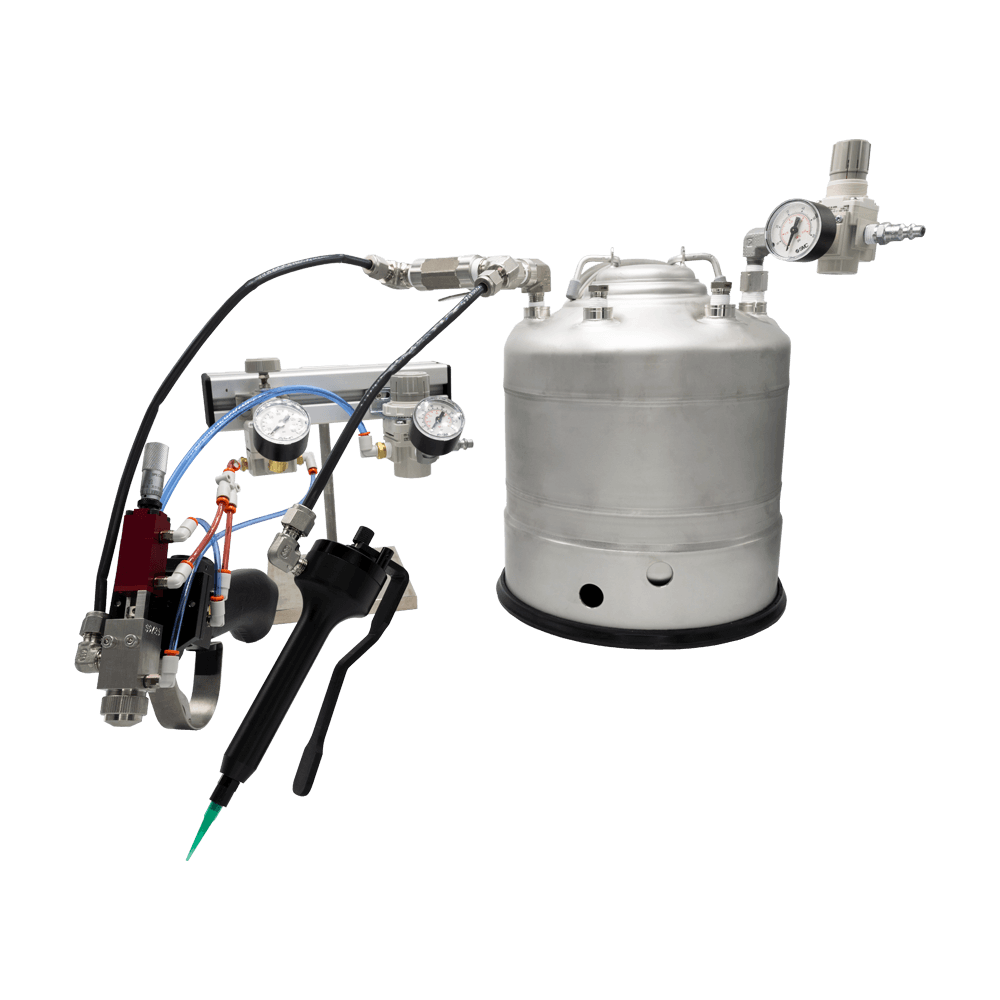

MCCS-SYS-1

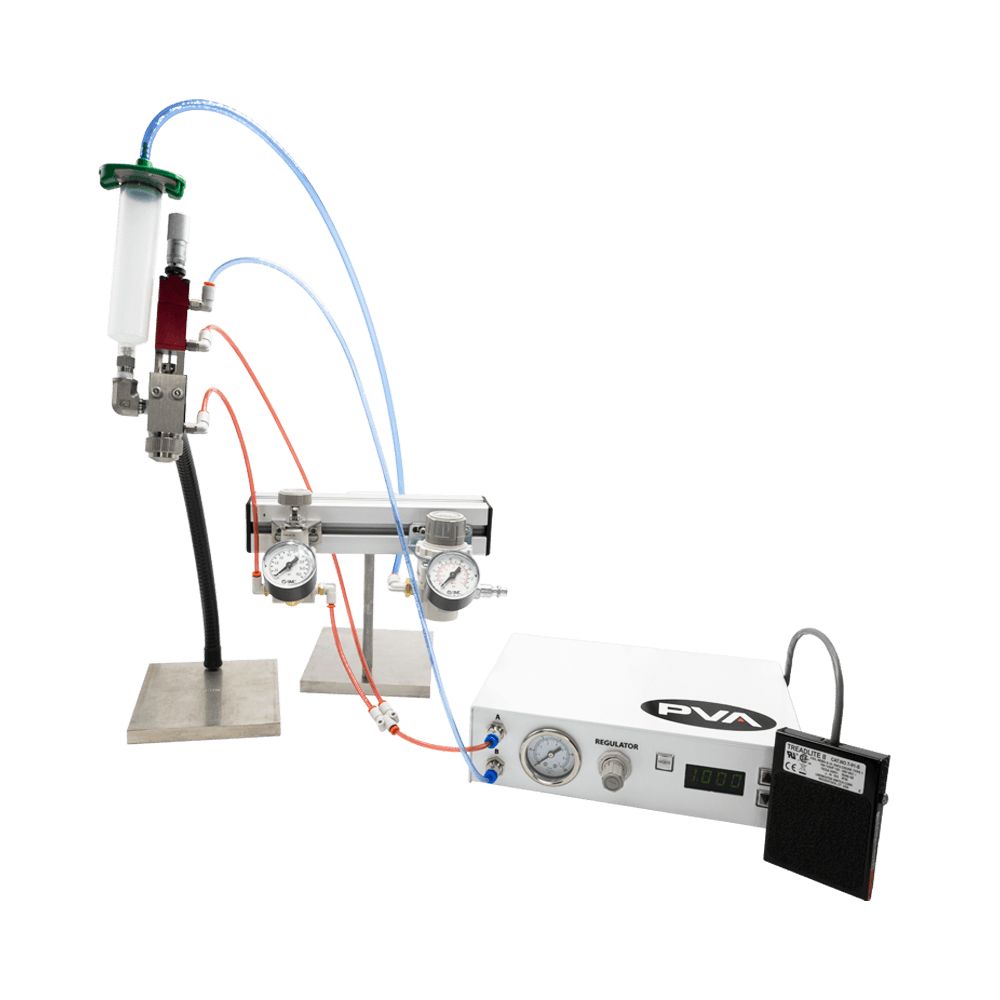

MCCS-SYS-12

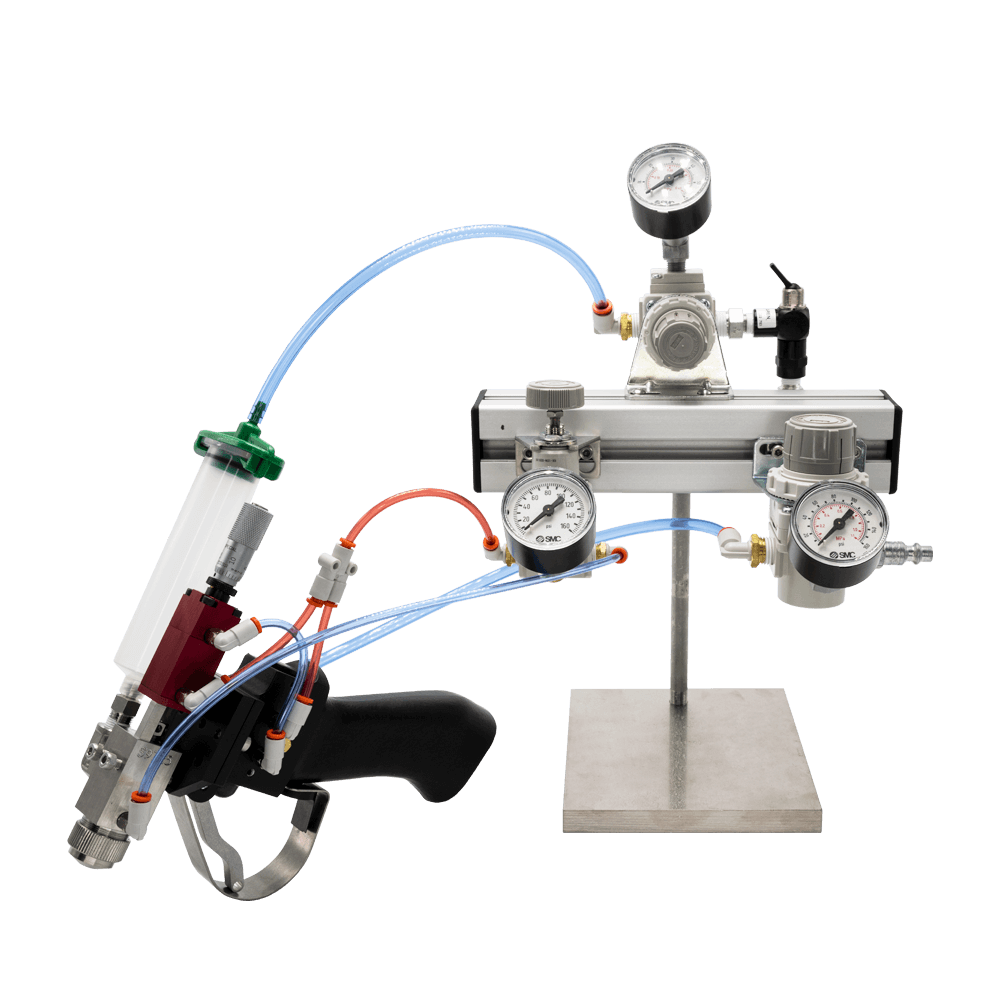

MCCS-SYS-14

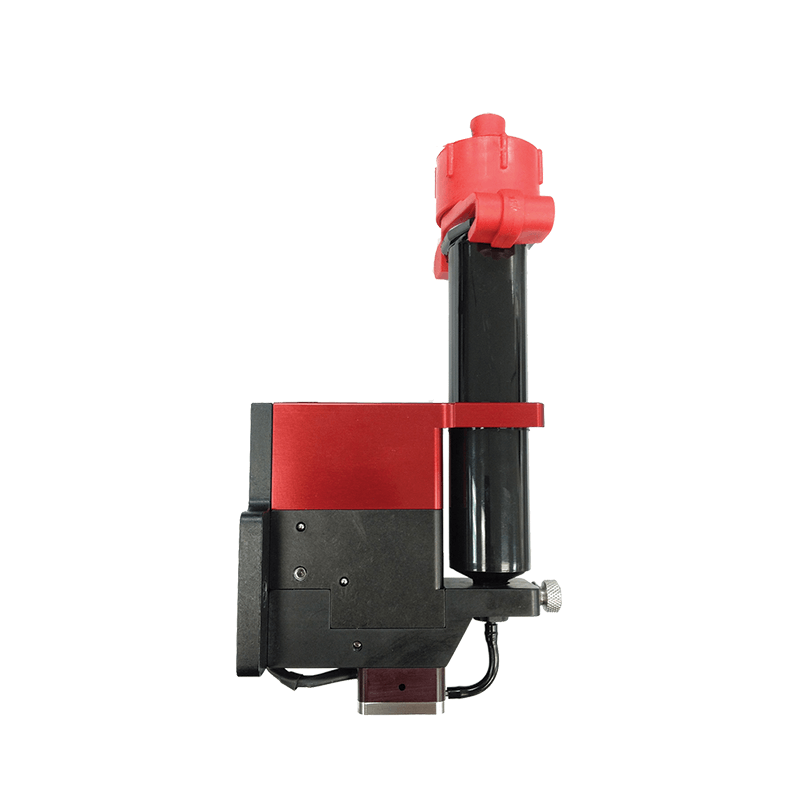

MCCS-SYS-2

MCCS-SYS-5

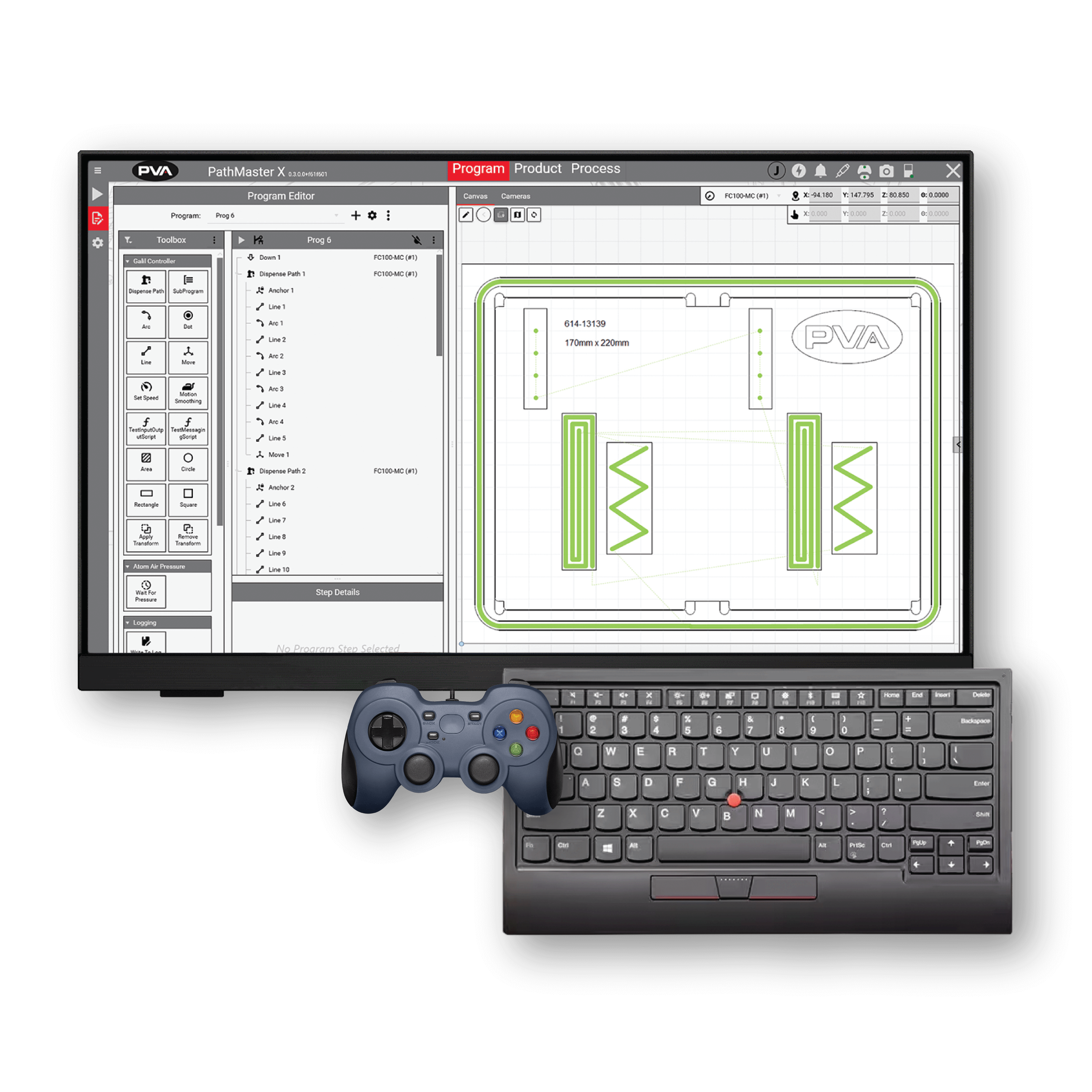

PathMaster X

PCS150

PDP

PVA 20/20

PVA350

RC200

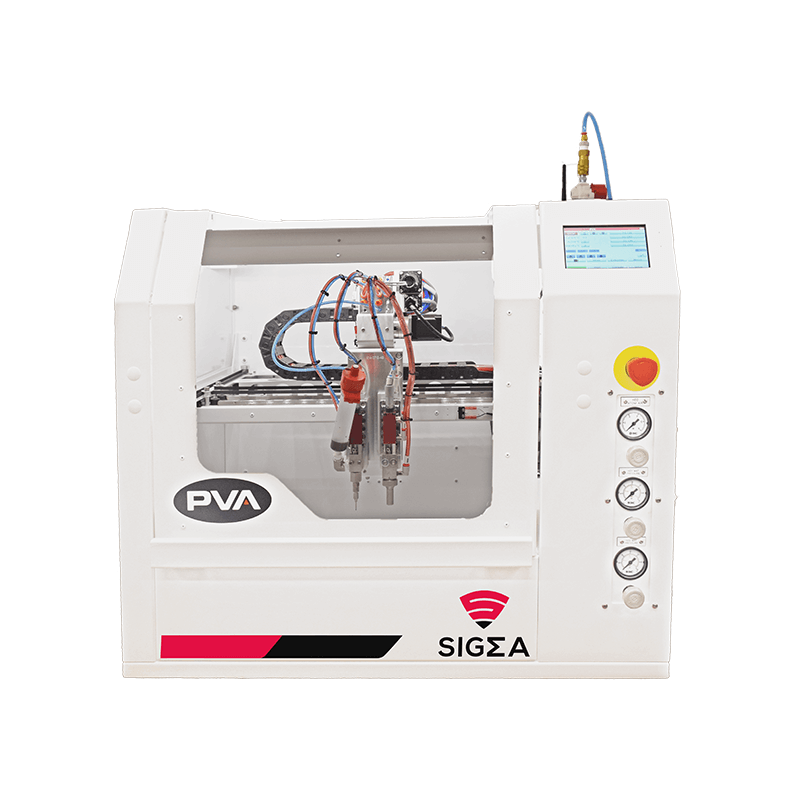

Sigma