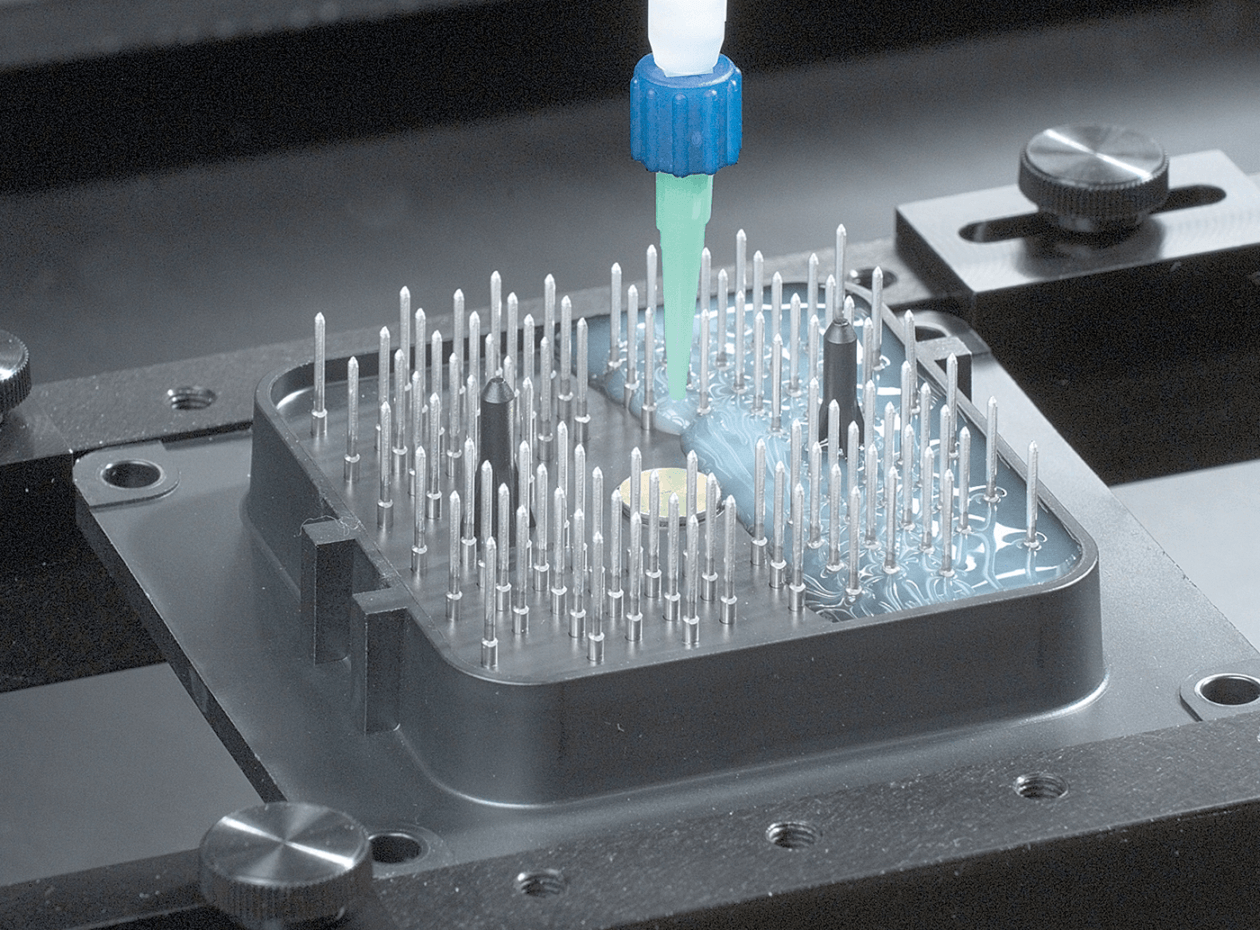

The process of filling an enclosure that holds electronic circuitry, with a liquid that when cured completely encases the unit. This provides mechanical stability during shock and vibration as well as environmental protection from moisture and foreign objects.

Products

View all

CA300

CAM200

Delta 6

Delta 8

DX150 Series

Endurance

FC100 Series

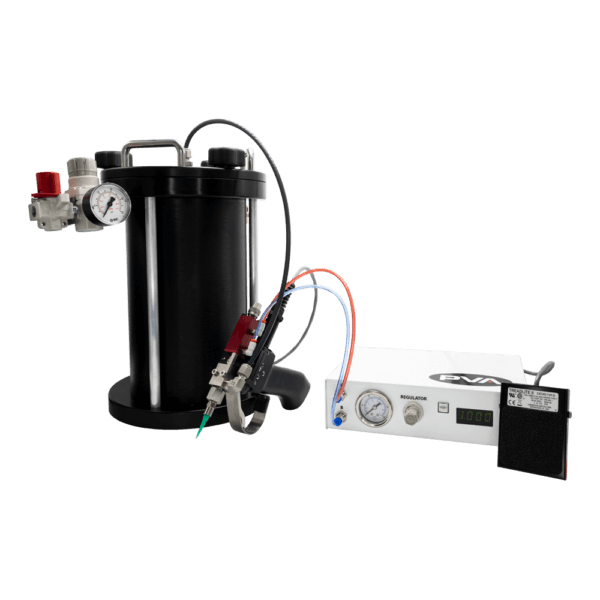

FC100-2G-H

FC100-2LT-1-H

FC100-5LT-1-H

FC300 Series

FCM200

Flex Cell

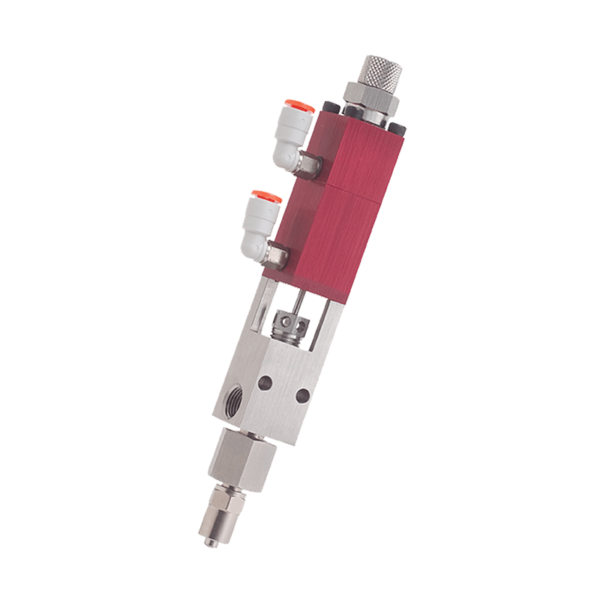

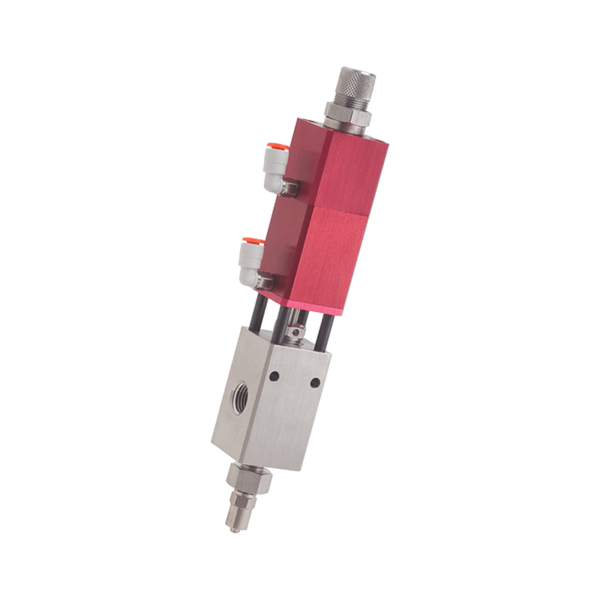

PC200R-SS

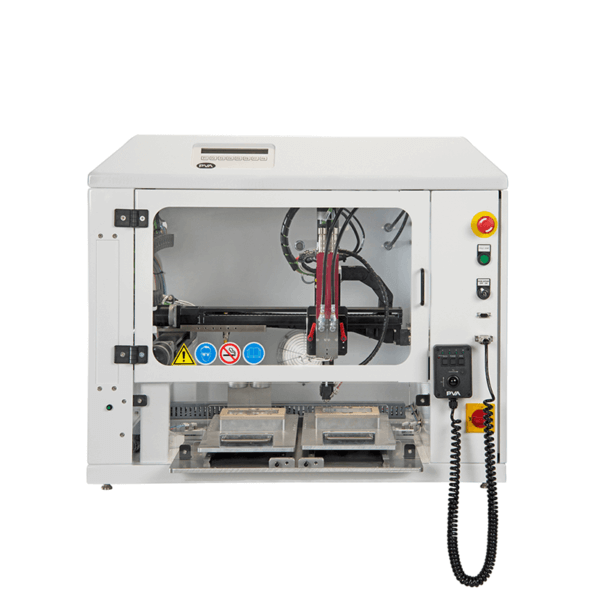

PVA350

SB300 Series

SB400-C