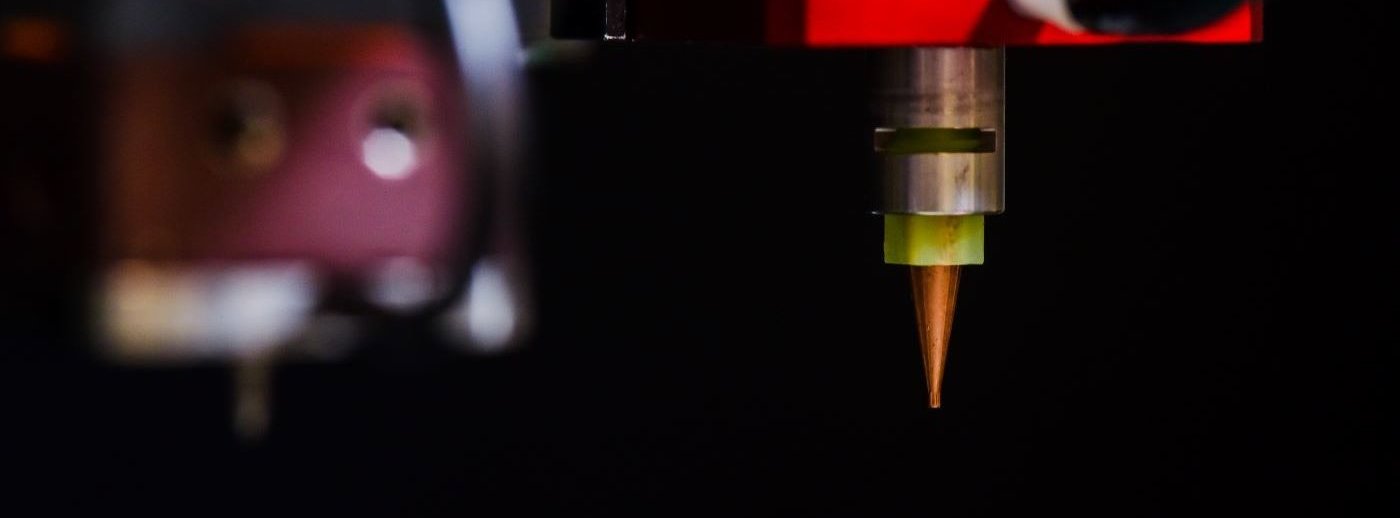

The process of applying an optically clear liquid to a digital display, such as LCD or plasma, to bond a cover glass and/or touch sensor to eliminate the air gap between each layer. This provides improved image clarity, especially in outdoor or bright light environments, improved resistance to shock and vibration, and additional protection against dust and moisture.

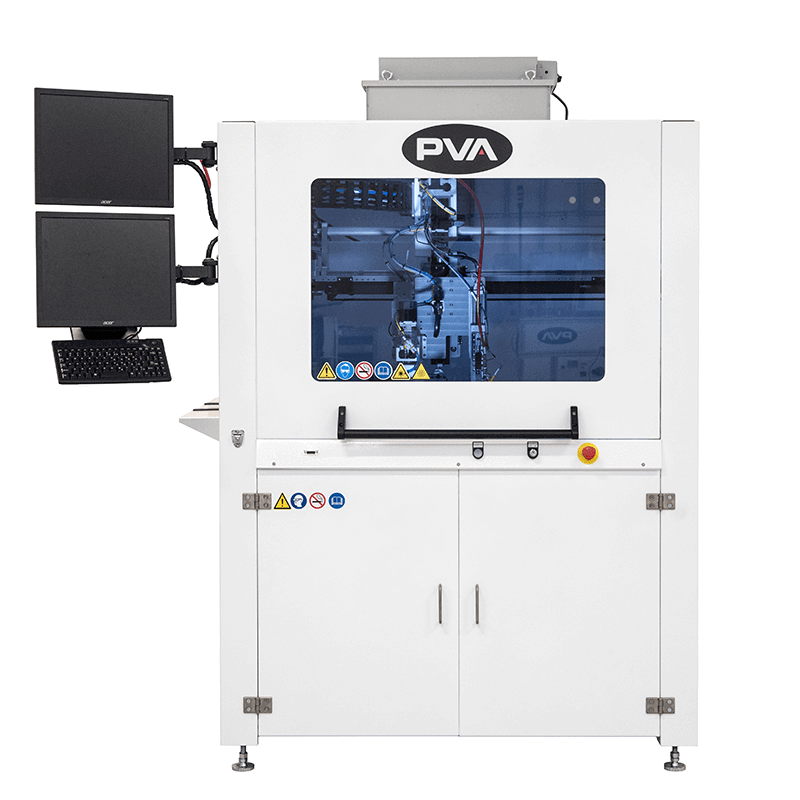

Products

View all