Continuous Film Calibration

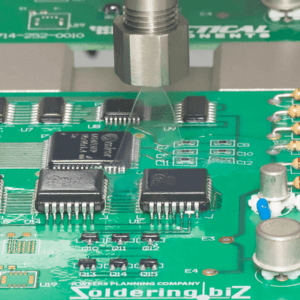

Continuous Film Calibration is a patent-pending process from PVA that rapidly examines an entire film pattern to determine and automatically adjust the fluid pressure to maintain the programmed width.

The Continuous Film Calibration option provides the most comprehensive pattern check and correction tool on the market. Unlike similar pattern check options that simply detect the pattern edges, Continuous Film Calibration not only confirms the film width but also detects any gaps or breaks in the pattern down to the pixel level.

Users can preset the desired pattern width and sensitivity. Any variation detected during a routine verification will result in recalibration of the fluid delivery system with no required operator intervention. Since the entire film is sensed at a single time and does not traverse over a stationary sensor, recalibration can occur up to four times faster than alternative solutions, resulting in significant savings in production time and coating material waste.

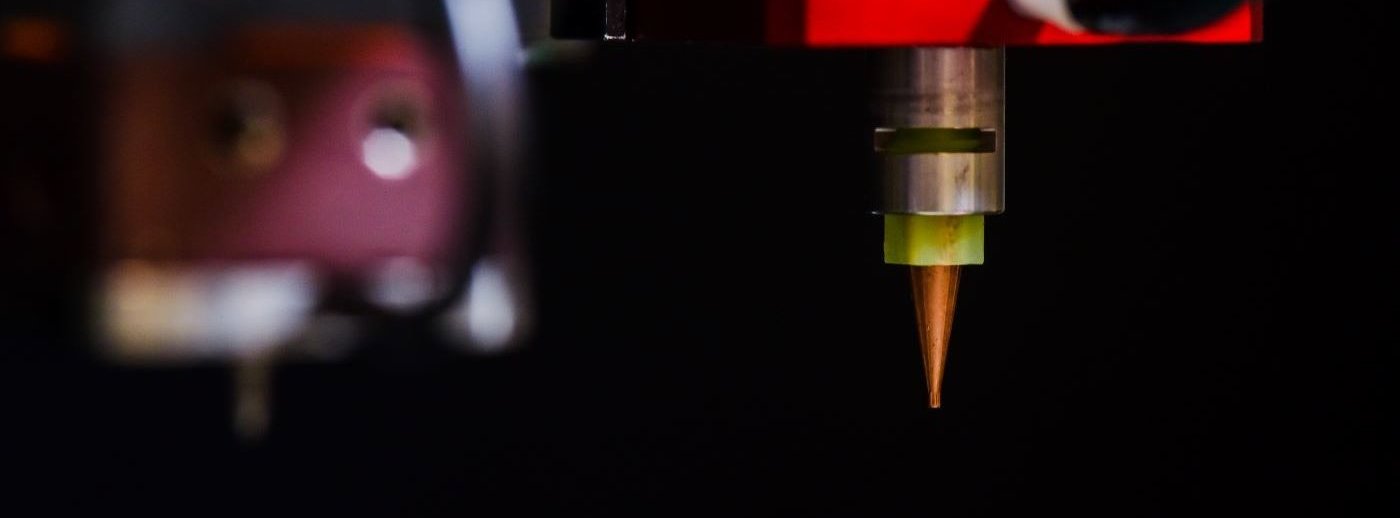

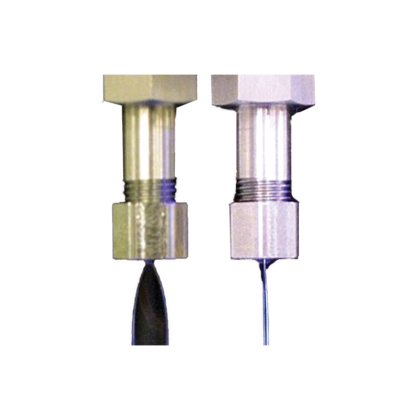

Continuous Film Calibration is currently used as an option with the FC100-CF Non-Atomized Film Coating Valve.