How Microdispensing Technology is Changing Medical Device Manufacturing

A revolution is upon us. Dispense pump innovation is quickly bringing improved accuracy, capability, and versatility to medical device manufacturers. This revolution not only opens the door to create production processes that were once unimaginable, but also increases the scope of chemistries that manufacturers can consider for these applications. The end result? Greater flexibility in achieving accurate results for small deposits of fluid with the option to choose rapid curing adhesives that reduce work in progress while improving bond strength.

Manufacturers are relying on their suppliers to use this updated technology to implement new processes. They are quickly turning in their syringes and the variability present in time and pressure dispensing processes for more accurate alternatives.

This is particularly relevant in applications requiring smaller dose volumes. Simple time and pressure dispensing systems carry a minimum 5-10 percent variation in volumetric accuracy. As manufacturing demands have required smaller deposits, that level of process variation is often unacceptable and physically unachievable in a manual process. Dispensing technology that can provide 1-2 percent shot-to-shot consistency is becoming the norm.

Demand for microdispensing technology has led users to seek more accurate applicators. In turn, manufacturers have enjoyed additional benefits of microdispensing pumps. These benefits include a significant reduction in minimum deposit volume, increased speed, better chemical flexibility, improved process capability, and subsequently better part quality and a significant reduction in waste.

Progressive Cavity Pumps

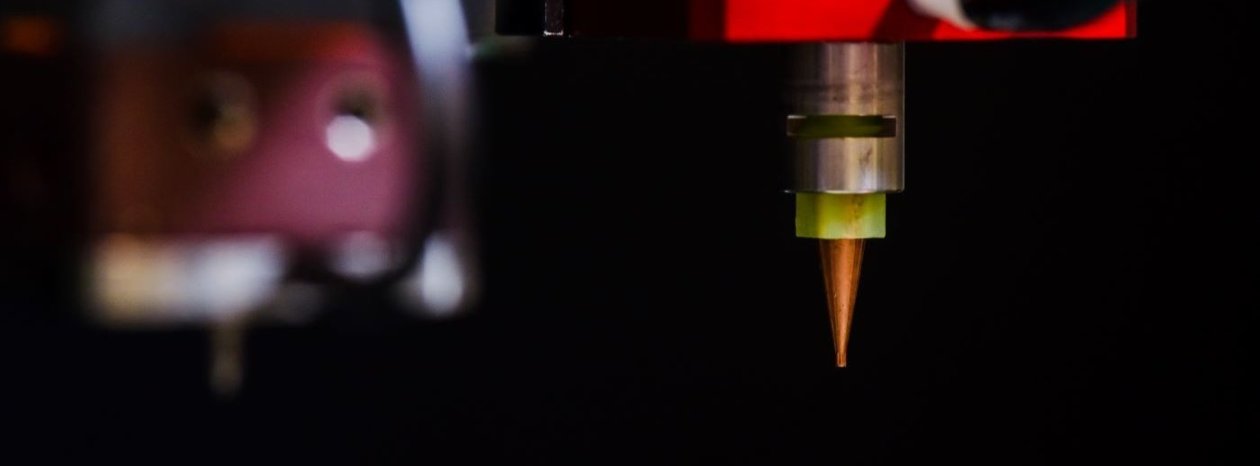

Progressive cavity pumps are positive displacement pumps by design. A helical rotor seals tightly against a molded stator as it rotates. Once sealed, fixed cavities are formed consisting of the resin to be processed. The rate of rotation directly impacts the pump’s flow rate. This relationship is direct; as the rotor RPM doubles, so does the subsequent flow rate.

By design, progressive cavity pumps self-seal as the rotor and stator meet. As a result, low viscosity fluids can be processed without concern of dripping or leaking. A progressive cavity progress is also continuous. There is no need to recharge or refill the pump creating a pulse-free dispensing process. Very little shear is created on the chemistry making sensitive or lightly filled materials acceptable to process.

Multi-component formulations can bring significant benefits to manufacturers from adhesion and mechanical strength to rapid cure times. Dispensing companies are typically weary of chemistries featuring wide mix ratios (out to 10:1) or large viscosity deltas. Wide mix ratios can make the resin and hardener difficult to mix sufficiently. These formulations require such a small amount of hardener that any variation in the mix ratio can change the chemical properties or impact the cure schedule. These issues are often compounded as the deposit sizes decrease because there is little room for error and even less mix time.

In moving the metering process right to the application point with progressive cavity pumps, users can have a high level of confidence in processing two-component chemistries, even if they have wide mix ratios or viscosity deltas. The resin and hardener are not exposed to each other until they depart the pump body and enter a static mixing tube. Since the mixing tube is disposable, daily maintenance is minimal. The segregation of the A and B components also prevents users from having to conduct any routine purging or cleaning.

The development of progressive cavity technology for 2K materials is driving an increasing number of users to these formulations. Two-part materials have traditionally been chosen for potting of electrical devices in a housing or a gasket to glue two housings. This was primarily due to limitations in valve technology. Progressive cavity pumps are now the option of choice for valve assembly, implantable devices, and the growing electronics assembly market.

Noncontact Jetting

Jetting technology has been present in the dispensing market for decades. This process brings a myriad of benefits to any manufacturing process. It’s fast. Jets can generate up to 300 drops per second. A rapid succession of dots generated quickly over a coverage area results in the formation of small beads of adhesive. Because the droplets are projected out of the jet valve, the processing height can remain fixed. Eliminating z-height movement can greatly decrease cycle time.

Jets are repeatable at very small deposit sizes. Much like progressive cavity pumps, jets should be expected to produce sub-2 percent repeatability. The advantage that jets have over progressive cavity, in addition to the processing speed, is the shot size of the droplets. Shots as small as 10nl are achievable with noncontact jets, making these valves an ideal choice as the desired dot or bead size gets smaller.

Limiting the number of parts that contact the fluid in your jet design not only reduces the cleaning time but simplifies the processing of more reactive chemistries that may need to be routinely purged from the dispensing system.

Manufacturers can also take advantage of the noncontact nature of jetting valves to help process parts that cannot be successfully dispensed on with traditional needle valves. As beads and dots get smaller in any needle application, the applicator’s z-height from the substrate becomes of greater importance. The gap height and robot speed will be the primary factors in setting the dispense volume in these applications. In parts that may flex or have high repeatability tolerances, a jet’s ability to dispense at the common z-height removes a major variable to achieving a consistent dispensing process.

Many devices are designed without consideration for downstream processes like dispensing. Companies like PVA often take on a consultation role to help develop solutions and implement processes that have never been done before, which is both exciting and challenging.