Interview with David Gomez for Mexico EMS

PVA is a global supplier of conformal coating systems, innovative fluid dispensing solutions and precision valve technology. The company’s customer-driven solutions are used worldwide in industries ranging from solar, semiconductor packaging, printed circuit board assembly, medical device manufacturing, and consumer electronics. Throughout the changing global manufacturing landscape, PVA remains committed to providing its customers with exceptional products and industry-leading global support. Our editor recently caught up with David Gomez, Regional Sales Manager for Mexico, to find out more about the company’s presence in Mexico as well as how it plans to continue growing and strengthening its presence in this region.

What actions and/or strategies led to PVA’s presence in Mexico? How long have you been involved in this region?

The pursuit of achieving customer satisfaction and approval led us to expanding our presence worldwide with Mexico being one of our first targets. It’s well known that ever since the late 80s and early 90s, Mexico has been a key player in the electronics manufacturing industry. Mexico provides industrial countries like USA, Japan, Germany and China the tools to acquire a low cost but high quality product throughout its friendly logistics, multiple ports of entry and economic tariffs.

Because of their geographic vicinity and historic relationship, the US was the country with the most influence during the development of the maquiladora industry in Mexico. PVA, along with many other suppliers to the American and international OEMs, was required to join this boom of investments in the Mexican territory almost from the beginning. I’m glad to say that PVA has excelled expectations by, for many years, being the first choice for dispensing capital equipment in Mexico’s maquiladora industry.

I started working at PVA in 2003, with the idea to be close to our main clients. At that time, I settled in Guadalajara and worked there for almost 5 years. Presently, I work out of Houston, Texas in order to hub to the many important cities in Latin America.

Is PVA selling directly into this territory or does the company rely on distributor relationships?

PVA prefers to work directly with our end user. Most projects are complex with many details and specifications that need to be discussed; thus we try to have a direct dialog with the end customer. Nevertheless, we have a very strong relationship with material manufacturers and their distributors for two reasons:

- With the eagerness to please our customer we tend to develop joint technical conferences with the manufacturer of the material we will be dispensing in a particular project.

- Our technology is developed hand in hand with the innovations of the material people. We’re in constant discussion with material manufacturers on the different paths the industry is moving to.

What percentage of your business currently comes from Mexico? Do you believe this amount will increase in the next year? How about the next five years?

At present time, Mexico accounts for one-third of our global sales. Throughout my 16 years in the industry, I haven’t seen a considerable drop in sales except for the 2008 automotive crisis, when the global market entered a standstill for many months. As our customers continue to invest in their Mexican operations, we are seeing a significant increase in activity. In 2018, Mexico was our fastest growing region and we expect the same in 2019. Certainly the USA-China trade conflict has contributed to this growth and is a key factor to our customers expanding their footprint in Mexico.

We foresee continued growth in Mexico over the next five years. US foreign trade relations will continue to be a factor in assessing the maximum potential, but we’re seeing our customers return in droves to the North American market. PVA has invested in diversifying our product line beyond our traditional selective coating market to take advantage of the opportunities unique to the Mexico market and have increased our presence in the region to better service our customers locally.

What are the key ingredients that PVA needs to succeed in the Mexican market?

Innovation – PVA is known for being the “think outside the box” supplier. We commit ourselves to meeting our customer’s requirements, and in this industry it often means we exceed our standard designs. PVA is very observant of industry tendencies and is always working on a dispensing solution or upgraded platform in order to provide to our customers with the most cutting edge technology. Another very important element that I personally emphasize when talking with my customers is our technical support force. Based locally in strategic cities throughout Mexico (Guadalajara, Chihuahua, Reynosa, Queretaro), the field engineers of this group have at least 5 years of experience and work directly for PVA. In Mexico, we do not rely on a representatives’ technical team to support our customers.

Which products/technologies do you expect to succeed in Mexico? Why?

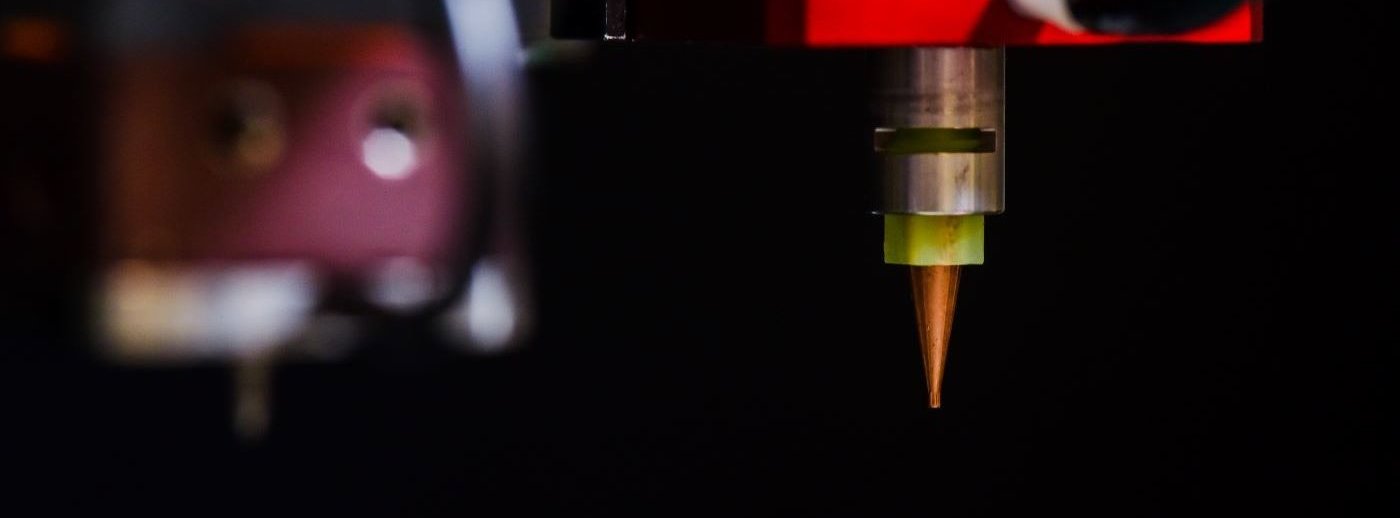

I’m confident that PVA has been successful in all technologies we have worked on. However, the conformal coating process is where PVA has been on top of the market by exceeding expectations. With this in mind, I expect PVA will play an important role in the solution making process of two other technologies, one being thermal conductive dispensing. We have developed the most reliable pumping systems for all thermo-conductive chemistries with the most aggressive fillers and/or highest viscosities. This unique fluid delivery, joined with very precise and customized robotics makes PVA the best solution in that market. The second technology is the optical bonding process. Our effort to developing a lean but accurate part handling for end product solution and our “know how’ on material dispensing, avoiding air entrapment and precise, repeatable shot quantities in the fastest rate possible will certainly be the go to solution for our customer.

What does PVA hope to accomplish in Mexico before the end of 2019?

Our target is to reinforce our Customer service team in Mexico in such a way that there’d be time for our Mexican field engineers to develop preventive maintenance calls, assessments on recommended spare parts and training to customer’s new personnel. Presently we are focused on setting up and launching mass productions in new equipment as well as stress calls on old machines. And obviously push our two technologies mentioned before in order to make my prediction a reality!