Needle Calibration: PVA Pro Tip #10

PVA Pro Tip #10: Mastering Stability: The Impact of Needle Calibration

Enhancing Process Reliability

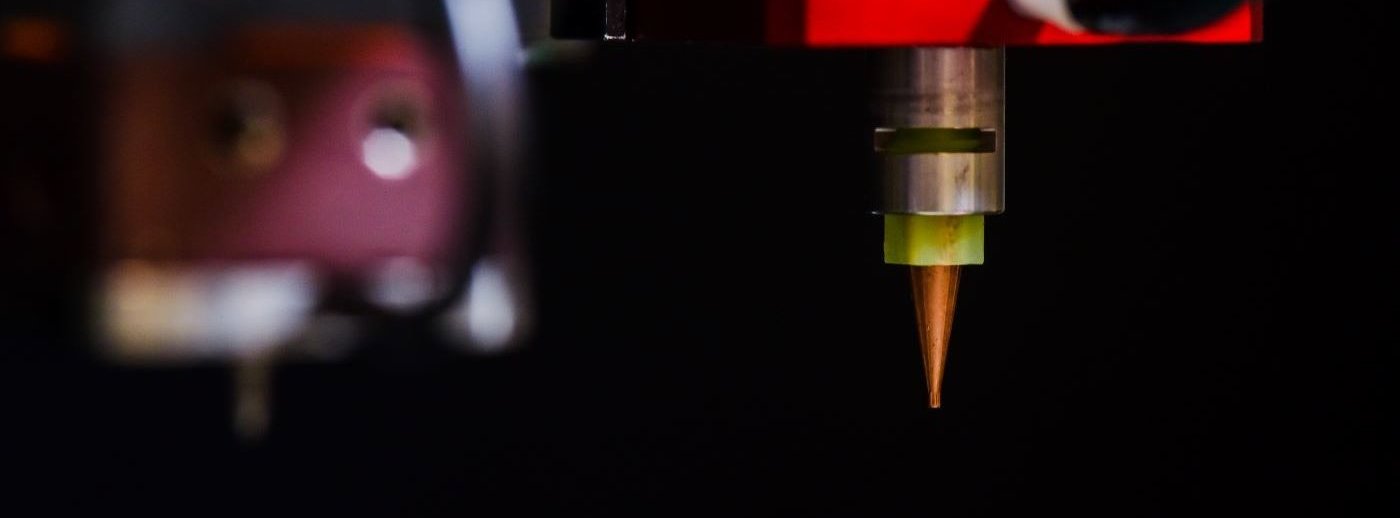

In your most demanding applications, confirming your dispense point remains consistent could be the most important factor in maintaining process stability. Utilizing PVA’s needle calibration option, you can confirm your application point remains stable periodically throughout the day, or simply when changing needle tips.

Transmissive optical sensors calibrate the needle position in the XY plane to a repeatability of 2 thousandths of an inch. Z height detection is repeatable to 1 thousandth of an inch.

What many users may not know is that our needle calibration option can also be in your spray coating application. A wide channel scanning area is ideal for calibrating your extended spray valve caps following routine maintenance.

If you’re interested in learning more about needle calibration, Contact PVA today and let us help make you a pro.