PVA and KIRSH Partner to Protect Riders from Brain Injury

This article was originally featured in the September 2018 issue of U.S. Tech.

By Emma Goldman, KIRSH Helmets

According to the most recent statistics from the National Insurance Information Institute, an average of 5,200 deaths in the U.S. every year are caused by motorcycle accidents. The cause of death in these accidents is frequently brain injury upon impact. KIRSH Helmets of Schenectady, New York, has partnered with Precision Valve & Automation (PVA) to develop a system for producing uniform safety helmets for people across many verticals, protecting brains and saving lives. KIRSH Helmets is developing a product that provides more for riders across all categories from safety to style.

Patented Silicone Liner

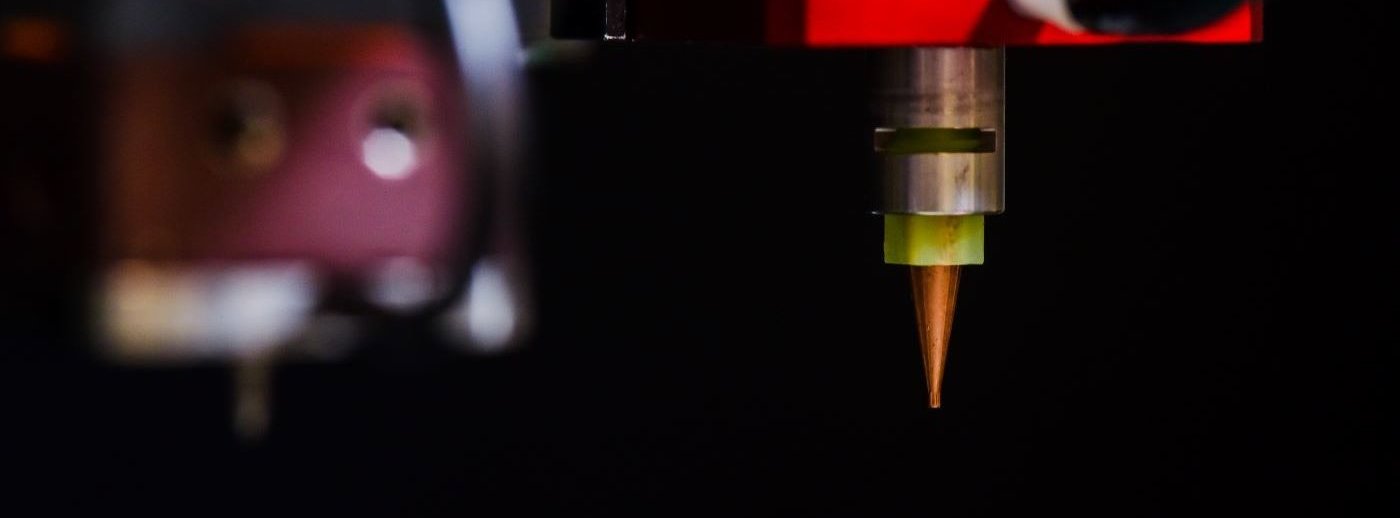

What makes the KIRSH helmet different is its patented FDL™ liner, filled with a special silicone gel designed to keep the rider cool and comfortable and also to reduce angular rotation of the head in the event of a crash. This silicone is mixed and deposited into the liner by PVA machinery, providing repeatable results across the entire manufacturing process.

The engineers at PVA specialize in automation, so while working with KIRSH to find the best solution, the two companies spent many months brainstorming and refining the development process. Once the final decision was reached, both teams were on the same page, with the exact results they were looking for. For a company like KIRSH Helmets, this kind of refinement time is vital. Allowing the design to evolve and change as more is discovered about technology is a necessity in this everchanging industry. Making small changes with big impacts, without jeopardizing production quality allows for optimization at every step.

The partnership has resulted in much growth for both companies. When KIRSH started out, the company mixed its formulas in a home kitchen, batch by batch. Working with PVA has allowed it to expand on its original processes and develop far more consistency with each new element. PVA’s automated software enables the machinery that performs the construction to store the information needed to make each helmet lining identical, regardless of where it is being made. This also allows for minor alterations throughout the process to be made, without the risk of damaging or altering the product unintentionally. KIRSH creates its products in the U.S. and final

assembly is performed by American veterans and those with disabilities.

Further Applications

This technology also assists KIRSH Helmets when working with the U.S. Department of Transportation (DOT) for safety testing. Impact testing with the DOT is one of the most essential steps in

the process for the company. Given the requirements for testing helmets, maintaining consistency in each one is a necessity and something that PVA’s machinery ensures.

Beyond motorcycle headgear, KIRSH is planning to share the helmet technology with other select industries as well. Professional sports participants have some of the highest rates for head injury across the board. This is one of the driving factors that the company has the capacity to change. The NFL has found that nearly 300 football players per year end up with concussions, some even leading to early death. Most of the concussions, 67.7 percent, are a result of the impact a player’s helmet in contact with the head of the player.

Personal safety is a never-ending concern for those who put themselves in danger, whether it be on the football field, or in public service, such as firefighters. KIRSH Helmets are built to serve a range of markets and change the way we think about personal safety. The partnership between PVA and KIRSH Helmets has the potential to change the rate of injury for the future and keep roads and homes safer along the way.

Contact: KIRSH Helmets, 251 State Street,

Suite 201, Schenectady, New York, 12305 / 1-855-504-4774

E-mail: customerservice@kirshhelmets.com

Web: www.kirshhelmets.com

Precision Valve & Automation (PVA), 1 Mustang Drive,

Cohoes, NY 12047 / 518-371-2684

E-mail: kjakiela@pva.net

Web: www.pva.net