UV Spot Curing: Pro Tip #13

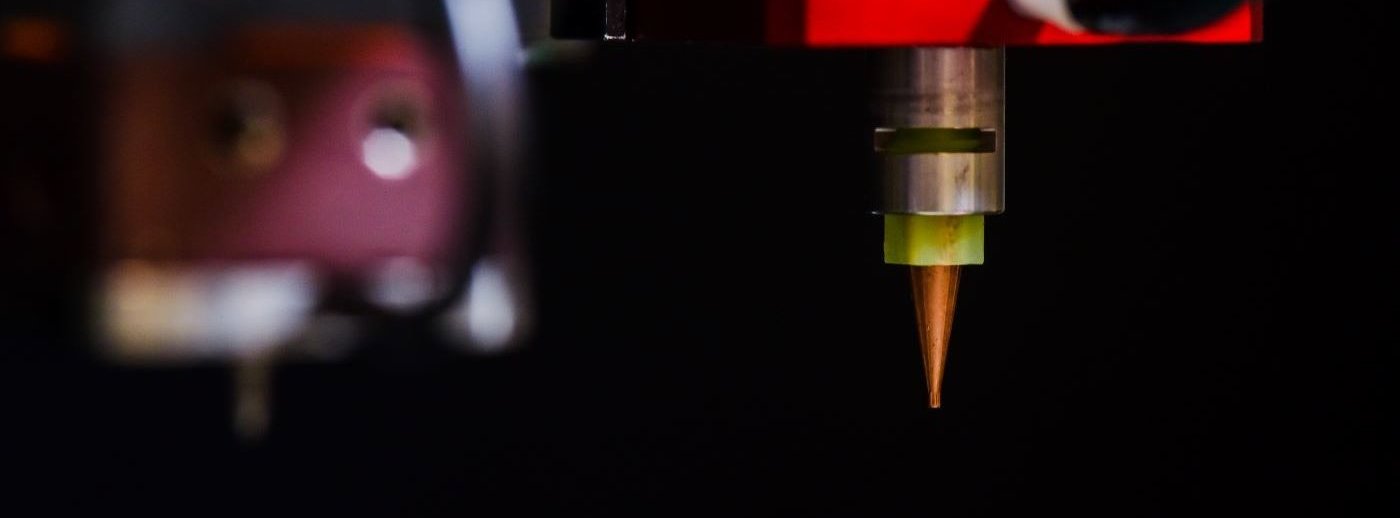

PVA Pro Tip #13: UV Spot Curing for Connector Coatings and Adhesive Control

Reducing Rework

If you are trying to maintain precise thickness and geometry to a UV curable material in a coating or encapsulation process, it can be difficult to limit the flow of material between the dispense and cure process. Integrating a UV spot curing system with your PVA coating, dispensing, or jetting system can help control flow and allow you to precisely set the chemistry thickness by immediately curing the material in the dispensing cell.

Implementing this simple process can be invaluable in coating applications that require coverage adjacent to a connector. Immediately curing the chemistry can prevent wicking onto contacts. Use a UV spot cure to “freeze” coatings and adhesives on leads or on component edges prior to flowing out. Exposing a target area for just a few seconds can make all the difference in your process and significantly reduce rework later.

For more information on UV spot curing or process implementation, contact PVA today and let us help make you a pro.