Long Term Reliability: Pro Tip #2

PVA Pro Tip #2: Long-Term Reliability for Dispensing Equipment

What to Look For in Dispensing Equipment Built for Long Term Reliability

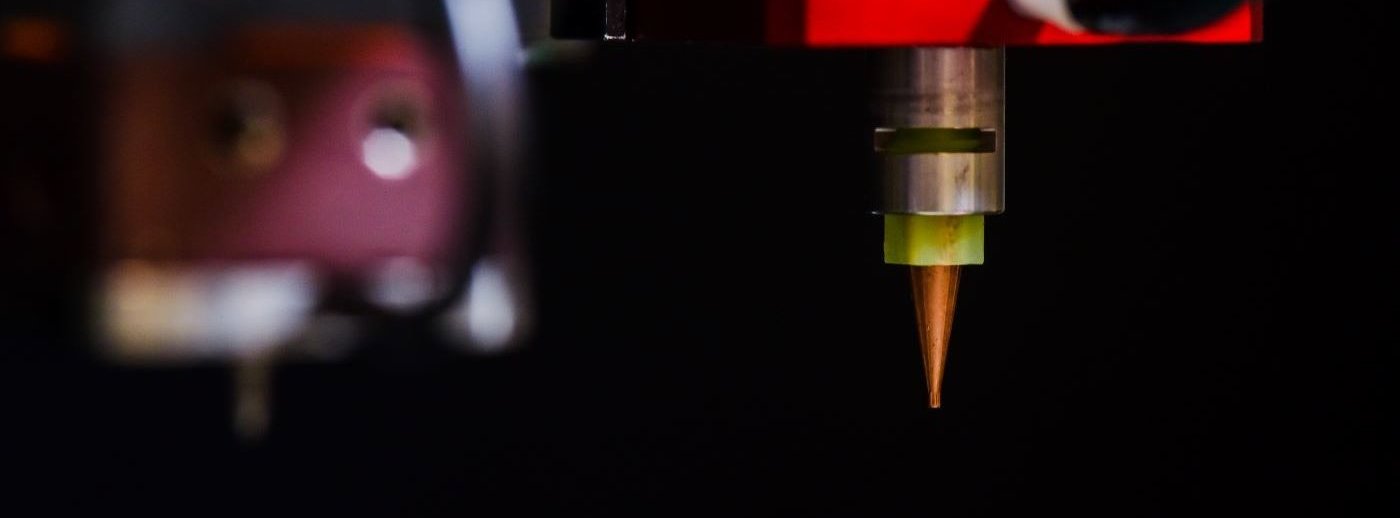

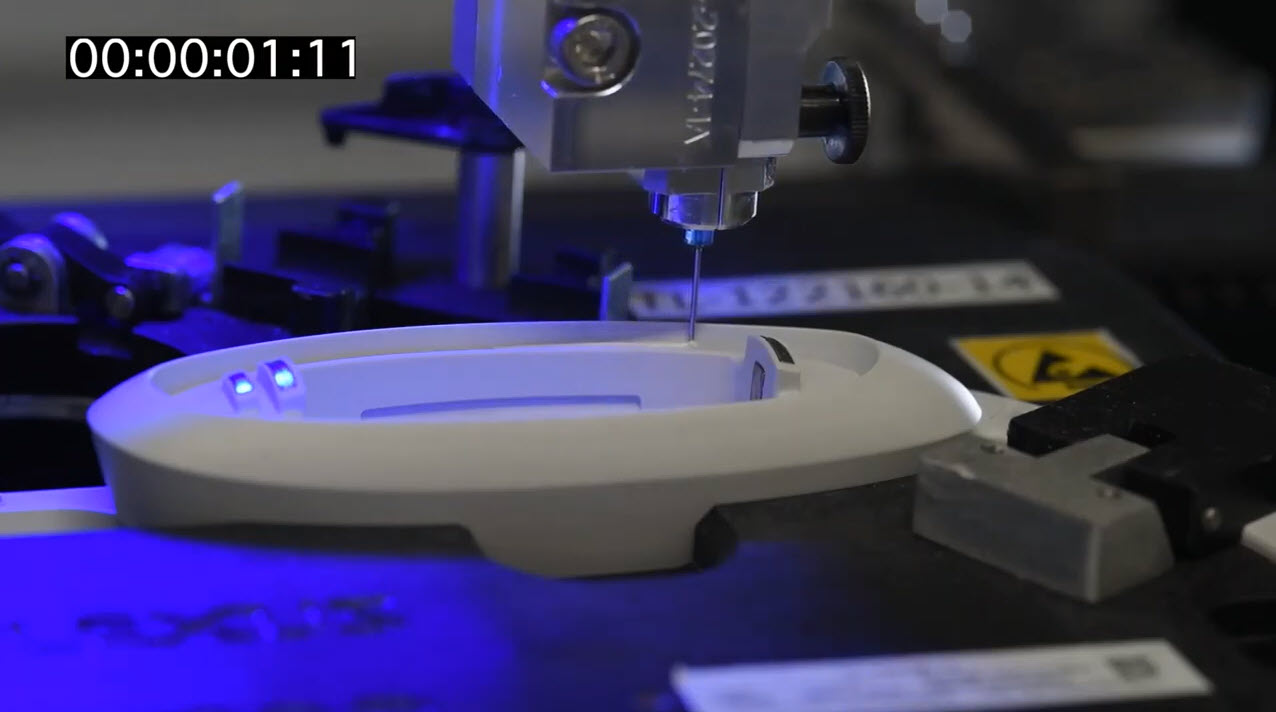

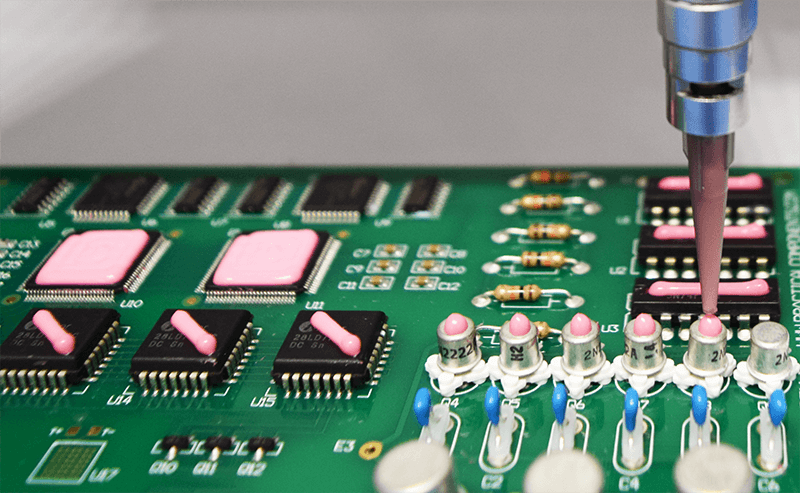

Abrasive chemistries can wreak havoc on dispensing equipment. Seals, pumps, and valves can prematurely wear leading to inconsistent results and frequent maintenance. For long-term reliability, look for dispensing equipment that features minimal restriction points. Next, be on the lookout for equipment that creates low shear forces on the material as both can damage fillers and erode seals quickly.

Alternatively, for high-flow dispensing requirements, look for hydraulic extrusion pumps and rod displacement metering systems with minimal chemistry contact. Finally, for smaller coverage areas requiring a high level of accuracy, progressive cavity pumps are ideal solutions.

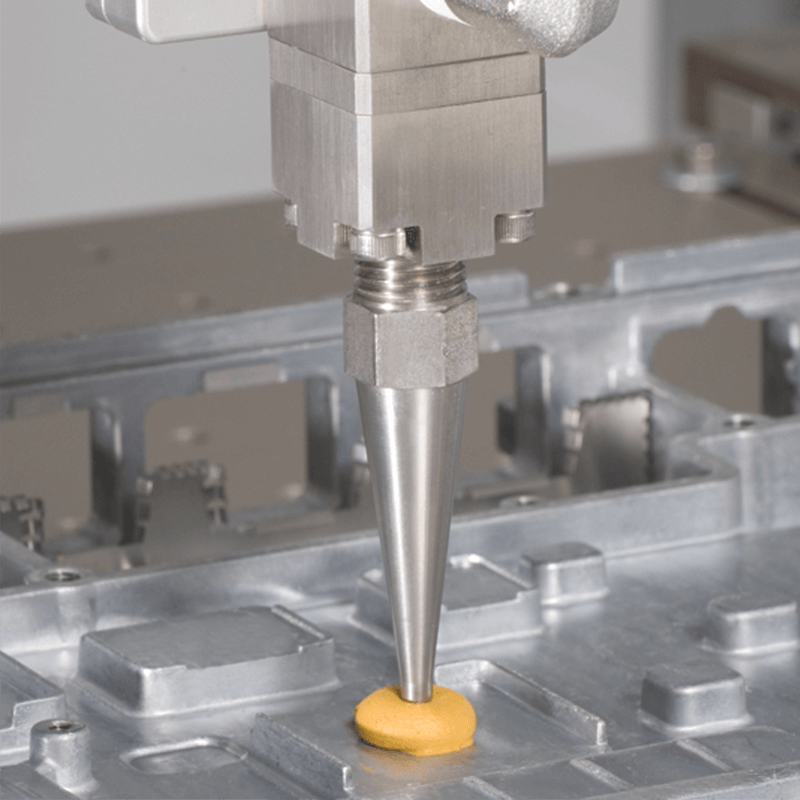

Extend Equipment Life with Carbide

Carbide is often used in lieu of softer metals to extend equipment’s working life. PVA offers several carbide valve solutions that extend life in adverse abrasive dispensing applications. These valves include the SB300-C and SB400-C, which both feature a special carbide rod. This is designed to resist wear against aggressive fillers. These carbide valves are suitable for a variety of applications.

Importance of Spare Parts Kits

Lastly, a crucial key component in your dispensing equipment’s long-term reliability is replacing spare parts. Subsequently, replacing spare parts at the recommended intervals is incredibly important, though often overlooked. PVA’s spare part kits include a variety of tools that will keep your equipment running efficiently. The PVA eShop offers several valve spare parts kits available. This makes it easy to stay on top of your recommended maintenance schedule and keep your dispensing equipment working as desired.

In conclusion, to achieve long-term reliability in your dispensing equipment, look for the following:

- Minimal Restriction Points

- Low Shear Forces

- Minimal Chemistry Contact

- Progressive Cavity Pumps are ideal for smaller dispenses

- PCP and PDP are great pump options

- Carbide Materials

- SB300-C and SB400-C are great valve options

- Spare Parts Kits

If you’re interested in learning more about how to achieve reliability in your dispensing process, Contact PVA today and let us help make you a pro.